Choosing Jigsaw Blades

A good machine can be half the battle when it comes to achieving satisfactory cuts with a jigsaw but you’re still going to be fighting an uphill struggle if you have the wrong blade for the job installed in it. However, there are a huge variety of options on the market and this abundance of choice can be a bit bewildering for inexperienced users. Therefore to make it a bit easier to find the right accessories for your requirements, we’ve compiled this quick guide to choosing jigsaw blades in which we’ll go over some of the most commonly required types.

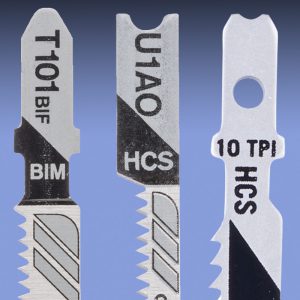

Shank Type

OK, so before you fit anything you’ll ideally want to have worked out whether your jigsaw takes T shank or U shank blades (which are identified by the shape of the end that goes into the machine and can be seen on the accompanying picture). T shank blades have become much more common over time and chances are this is what you’ll need, especially if your machine was manufactured in recent memory. However, U shank blades can still be easily found for the jigsaws that take them, and in fact Ryobi make a set of blades which incorporate both shanks – which could be an ideal starting point if you’ve found an old jigsaw and have no idea what type it takes. Some especially old jigsaws take a U shank blade with an additional hole in it, and unless you can modify a new blade to fit, these are becoming much harder to replace.

Length

A blade that isn’t long enough for the task at hand will quickly cause problems so you’ll want to make sure you’ve picked a suitable one if you’re cutting through deep materials but bear in mind there are two different figures which can be quoted here: Total Length, which usually runs from the tip of the shank to the tip of the blade, or Cutting Length, which corresponds to the actual part of the blade that does the work. As well as making sure you have sufficient cutting length to make it through your workpiece, it’s a good idea to leave around 25mm of additional legroom due to the reciprocating nature of the tool.

Workpiece Material

You’ll probably come across blades for wood or metal in your local hardware store but there are also more specialised options available, including blades for ceramics, tiles, fibre cement, sandwich panels, laminates and soft materials like leather or rubber. Blades for these materials will generally be labelled and sold as such but due to similarities between materials and constraints of product titles or descriptions it may not always be immediately obvious if there is a blade on the market that matches your requirements. A good example is plastic, which is a fairly common material to cut with a jigsaw – however relatively few jigsaws blades are explicitly categorised for this purpose. In fairness there are a multitude of different types of plastic you may need to cut but for most home & garden building materials a blade for wood will do the job. So if you can’t find a blade that’s advertised as being suitable for the materials you have in mind, it’s worth doing some research on the internet or asking a staff member whether they have any recommendations. We have made the Jigsaw Blades category on the Tooled-Up website a bit easier to navigate by introducing filter options for common materials so you can narrow down your search results if need be.

Blade Material

You may have also noticed that jigsaw blades themselves are made out of a variety of materials. In many cases this will be printed on the blade as well as the packaging for quick identification, typically in the form of an abbreviation like HCS. Let’s take a quick look at some of these and their various strengths (or weaknesses).

HCS Jigsaw Blades

HCS stands for High Carbon Steel. These blades can withstand flexion well and are generally inexpensive, making them a popular everyday choice for soft woods and light duty plastics. As the metal is fairly soft and pliable these blades can be expected to survive bends and curves but the teeth will wear out faster than with other types, especially if used on tougher materials.

HSS Jigsaw Blades

HSS stands for High Speed Steel and is commonly used to make drill bits for metal (before its invention, metal would typically be machined at low speeds to avoid wearing out the tooling). Likewise, jigsaw blades made from HSS are more often than not designed for metal as well. While HSS teeth can withstand repeated cuts through tougher materials, the metal itself is quite stiff and inflexible, meaning that bends and curves can cause it to break prematurely.

BIM Jigsaw Blades

BIM stands for Bi-Metal and is a composite, commonly consisting of the two previous materials outlined above. By using HSS for the teeth and HCS for the main body of the blade, the shortcomings of both materials can be overcome, creating a blade that will flex without breaking and cut through hard materials without dulling the teeth. This makes these blades ideal for curved cuts in tougher materials like hard woods and metal. Due to the extra manufacturing processes involved, BIM blades can be amongst the most expensive to buy, but their increased durability means they can be viewed as a long term investment.

TC Jigsaw Blades

TC stands for Tungsten Carbide, which is an extremely hard material commonly used in industrial tooling. TC blades are not made purely from tungsten carbide but instead they have either carbide teeth or, more commonly, a layer of tungsten carbide grit which is applied to the cutting edge instead of saw teeth. This is commonly used when cutting through abrasive materials like kitchen or bathroom tiles, fibre cement boards, plasterboard or glass fibre reinforced plastics. Similar blade technologies can be identified by terms like TCG, RIFF and Diamond.

Tooth Configuration

Unlike the last example outlined above, the vast majority of jigsaw blades will have some kind of saw tooth configuration which will determine how quickly, neatly and effectively they can accomplish any given task. When it comes to saw teeth, one of the most basic principles is that a high tooth count makes for a finer but slower cut, while a low tooth count makes for a faster but rougher cut. The workpiece plays a big part too: jigsaw blades for metal can quickly be identified by their especially fine teeth, while a coarse cutting blade for soft woods will typically have much larger teeth which enable it to quickly power through the material. Most jigsaw blades are designed to cut on the up stroke and have teeth that point towards the shank, but you can also buy blades with a reverse configuration, commonly known as downcut or reverse tooth blades. The primary reason for this is that when running a standard jigsaw blade along the top of something like a laminated worktop, the top side of the work surface will have a much rougher finish as the teeth are pushing the laminate away from the material as they cut their way through. This can be avoided by placing on the jigsaw on the opposite side of the material, but another solution is to install a reverse tooth blade which will produce a much neater cut through the tool side of the workpiece without having to flip it over or work from the underside. The downside of these kinds of blades is that they can’t be used in pendulum modes, meaning that working time can be prolonged, especially during longer cuts.

Aside from this, there are lots of other considerations in jigsaw blade design. Whether the teeth are milled, ground, side set, wavy or straight are all factors that can contribute to a blade’s performance, cutting speed, finesse and longevity. Without wanting to get too into depth in this quick guide, any advantages conferred by these variables can often be identified by consulting the blade packaging or looking up the partcode online, which should tell you the blade’s particular strengths and any recommended applications.

One last point (if you’ll excuse the pun) is that some jigsaw blades have specially designed plunge tips, meaning they can be inserted into the middle of soft woods and similar materials rather than having to be started off from the edges. Any normal jigsaw blade can be used for cut-outs too, usually by first drilling a starter hole to slot it into. However if plunge cuts are a regular part of your working routine and you don’t want to have to rely on additional equipment, a jigsaw blade with a plunge tip may be a worthwhile investment.

Blade Thickness

Because jigsaw blades are long, thin strips of metal which are only supported by the tool at the shank end, they can often leave angled cuts through thicker materials due to the end of the blade wandering during use. This is often seen as a limitation of jigsaws themselves (and to a degree it is) but in many cases it can be overcome by careful blade choice. One of the most effective ways to ensure straight cuts from top to bottom is to choose a blade with increased thickness which will be much less prone to wandering. Bosch denote blades of this type with a “P” suffix on the product code – for example, the T1044 DP wood cutting jigsaw blades – and many other manufacturers print these equivalent codes on their own products for easy identification.

If you want to make straight cuts that you can hold a square up to, a thick blade may be ideal for the job but there are many cases when thinner blades prove their worth too. As well as offering increased maneuverability that makes them well suited to negotiating curves and for general purpose use when cutting sheet goods, thinner blades also place less demand on the tool’s motor. Though this is not typically a concern when connected to mains power, it means runtime can be theoretically extended with cordless tools, enabling you to work for longer on a single battery charge. Thin blades designed specifically for cordless jigsaws include the Makita Super Express series, available as a three piece set for wood and metal.

Conclusion

Of course, this is only a short guide to some of the options and variables on the market and only scratches the surface of what’s available. The best way to ensure you’re choosing the best jigsaw blade for your requirements is to consult the manufacturers description and intended usage, and most new blades are supplied with basic usage instructions and application guides. To make it easier to navigate through the various options we stock on our website, we have added filter options so you can select from options like shank, length and material type to help narrow down your search results.

Categories mentioned in this article:

QUite useful information. What blade would you recommend for fibre cement panels 12-20mm thick?

Hi Patryk – Bosch make a carbide tipped blade called the T141HM which looks like it would be suitable for your application – it’s recommended for fibre cement boards from 5mm up to 50mm. You can check it out on the Bosch site https://shop.bosch-professional.com/gb/en/accessory/t-141-hm-special-for-fiber-and-plaster-jigsaw-blades–2592803 or on our website here: https://www.tooled-up.com/bosch-t141-hm-fiber-plaster-cutting-jigsaw-blades/prod/60463/. Alternatively there’s the T341HM which has a bit more capacity for not much more money. More details at: https://shop.bosch-professional.com/gb/en/accessory/t-341-hm-special-for-fiber-and-plaster-jigsaw-blades–2592804 or: https://www.tooled-up.com/bosch-t341-hm-fiber-plaster-cutting-jigsaw-blades/prod/60464/ hope that helps!

A convenient guide, thanks, Patryk Tokarek!

Very informative every paragraph of your article. I read it several times and achieve a lot of information. All the section Sank type, Length, workpieces material, blade material, Tooth Configuration, blade thickness just osam. Special thanks for tooth configuration.

I am impressed with your courtesy; Even after writing so long and informative articles, you still call it a short guide.

Very good document, exactly what I wanted to know, thanks

Excellent info

Thanks

Very informative

Apparently my old black & Decker jig saw will only work with U shank blades and my new saw won’t as the u shanks keep falling out of it

That sounds about right – it only tends to be the older jigsaws that take U shank blades these days. You could always try those Ryobi universal shank blades if you’re looking for something you can use in both machines?

I have an old Makita JG1600 jig saw and I wanted to make sure that I was buying the correct blades for it. I usually only work with wood including solid, ply, and composite . Can anyone shed some knowledge on this, thanks

I have an old Black and Decker jigsaw 7504 that I want to cut straight lines, no curves plexiglass (.093 thick). What blade should I buy?

Wow, that really is an old jigsaw (by the looks of it). While I wouldn’t like to say for certain, it looks like that machine will only take the older style of U shank blade with the hole in it, in which case your options are unfortunately going to be severely limited in the present day marketplace. I don’t know how important the cut quality is for your project but if you want to get the best results it may be worth investing in a newer machine just so you can use the much wider variety of T shank blades that are available. For example the Bosch T 101 A blade is ideal for straight cuts through Plexiglass. You can usually pick up a half decent jigsaw for not much money on the second hand market so I don’t think you’d have to spend much more to go down that route – otherwise, I’m afraid I can’t see a great deal to choose from and it may just have to be a case of making do with what’s available. These Vitrex tungsten carbide blades have the older style Black & Decker fitting and they’re described as being suitable for fibreglass and plastics so they might do an acceptable job?

I have a Bosch JS5 jig saw that uses U shank blades, any idea how old this saw may be, have had a long time hardly been used. T shank blades look to be more popular.

I’m not familiar with the Bosch JS5 but from the exterior it looks like it is from the same lineage as the current Bosch Professional range and if I had to guess I would say it might be from the early 00’s…? I could be completely wrong on that though. But yes, the T shank system is much more widely used these days, primarily because these blades can be swapped out quicker and easier in newer jigsaws.

I need to cut three-quarter inch rubber stall mats. It will be all straight cuts. What blade do I need?

Hi Jean, if you take a look on our website in the Jigsaw Blades category you can filter out all the blades for Soft Materials and this will show you a handful of blades that are suitable for rubber. For example the Bosch T 313 AW jigsaw blades should give you a clean, straight cut in rubber which less than 100mm thick (approx 4″ ). You can view them here.

Very helpful, I inherited the jigsaw but have no blades and this is a very nice guide for a first time user and buyer. Thank you!

hi i have been given a challenge SSE55G1 jig saw and wan,t to know what blades it

uses.

Hi Martin, if I’m not mistaken Challenge is an Argos “in house” brand which is only normally sold in Argos stores. It’s quite difficult to find any information on that model so I wouldn’t like to say for sure. Might be best to try a couple of cheap blades and see what works (unless anyone is able to confirm in the meantime)

I have a black & decker ks633e what type blade fitting do I need t shank or u type ?

I suspect Black & Decker could have released a few different jigsaws with that model number over the years but it looks like it requires a U shank blade.

Hi l have Makita 4350FCT jigsaw. l want to cut solid oak 45mm thickness kitchen worktop. What type blade should l buy? Thank you.

You’d want a T-shank blade that’s designed for hard wood (and which is longer than 45mm obviously!) I’m guessing you’re probably making a cutout for a sink or something similar? But in any case, this Bosch set for example includes blades which are designed for both straight and curved cuts so should hopefully give you everything you need. With laminated worktops you need to be careful of chipout but if it’s a solid block of wood this won’t be an issue.

Hi can you buy a blade for cutting metal with a total blade length of 100mm ? This is for a Bosch jigsaw

This was very helpful – thank you!

Hello, I have an old penncraft saber saw, variable speed model 4952. The blades are the U shank with a hole. Can I use the U shank without the hole or will it not hold? To remove the blade, there is a hex wrench and 2 screws. I have not been able to find any blades with the hole. Thanks!

Hi Leslie, I’m afraid as I’m not familiar with that saw I don’t know what the answer is – I suppose the good news is at least you should be able to pick up some blades fairly cheaply to give it a go?

Nice article thanks.

I have an Erbauer EIS750 jigsaw and need to cut Marvec 0.8mm plastic sheets vertically and horizontally- what blade do I need?

I’m told it needs to be fine toothed. Does that mean blades for metal are suitable.

I have used metal bits to drill holes at a slow speed on the same material.

Is the principle the same?

Having had a quick look I can’t see anything which stands out as being purpose built for such a material – you can get jigsaw blades for plastic and PVC but they’re usually intended for thicker materials than that, so I would guess that a very fine toothed metal cutting blade like the Bosch T118 G might indeed be worth a try at least. Bosch don’t recommend them to be used on plastics and they’re intended for straight cuts, but they are designed for very thin metals (0.5 -1.5mm thickness). These aren’t the only options of course but if you can find something similar with a very fine tooth I would imagine that’s going to be your best bet – it’s not something I’ve tried myself though so there may of course be a much better solution out there which I’m not aware of.

Hi! Can someone help me to find out, what kind of shank goes with semi old Kraft zigsaw?

I’m looking for the best jigsaw blade for cutting thinscape countertop material. I know I need a carbide tip, but what about the tooth count, standard or reverse tooth. Cutting out two holes for drop in sinks.