Brad Nails

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Brad Nails

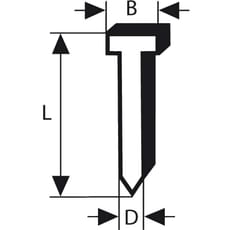

Brad nails are fine-gauge finishing fasteners specifically designed for delicate woodworking and trim applications where subtle, nearly invisible fixings are essential. Unlike heavier framing nails or clout nails, brad nails feature a small cylindrical head that can be easily set below the surface and filled, making them the preferred choice for finishing work, cabinetry, architrave, skirting boards, and decorative mouldings. Predominantly manufactured in 18 gauge (1.25mm diameter), with some 16 gauge and ultra-fine 23 gauge options available, these slender fasteners minimise splitting in thin or delicate materials whilst delivering sufficient holding power for lightweight joinery applications.

The selection at Tooled-Up.com includes brad nails from industry-leading manufacturers such as DeWalt, Bostitch, Makita, Milwaukee, Bosch, Arrow, and Tacwise, ensuring compatibility with all major brad nailer models. Options range from galvanised brad nails for moisture-resistant applications in kitchens and bathrooms, to premium stainless steel variants for external use or coastal environments, plus standard bright steel brads for interior joinery. Lengths span from 15mm micro pins for delicate veneer work up to 64mm for securing heavier trim into solid substrates, accommodating various material thicknesses and project requirements.

Brad nails are supplied in collated strip format designed for automatic feeding through nailer magazines, with most professional-grade options featuring adhesive or wire collation for reliable, jam-free operation. Whilst pneumatic brad nailers remain popular on traditional job sites, Tooled-Up stocks increasing numbers of fasteners compatible with battery-powered cordless models from Bosch, Milwaukee, and DeWalt, reflecting the growing preference for portable, compressor-free solutions amongst modern tradespeople and serious DIY enthusiasts.

Jargon Buster

- Gauge: The thickness measurement of the nail wire, expressed as a number where higher values indicate thinner nails. 18 gauge (1.25mm) is the standard brad nail size for most trim work, whilst 16 gauge provides additional holding strength for heavier applications and 23 gauge creates virtually invisible fixings.

- Galvanised: Brad nails coated with a protective zinc layer to provide corrosion resistance, making them suitable for moderate moisture exposure in kitchens, bathrooms, utility rooms, or unheated workshops where standard steel fasteners would rust.

- Collated: Nails joined together in strips using adhesive, wire, or plastic, allowing automatic feeding through a nailer's magazine for rapid, continuous firing without manual loading between each fastener.

- Headless Pins: Ultra-fine 23 gauge fasteners (also called micro pins or mini brads) that leave virtually no visible mark, used for the most delicate mouldings, picture frames, and veneer work where even small holes are unacceptable.

- Finish Nails: Slightly thicker cousins of brad nails, typically 15 or 16 gauge with small heads, offering greater holding strength for heavier architectural mouldings, thicker skirting boards, and applications requiring more substantial fixing power.

- Stainless Steel: Premium corrosion-resistant brad nails manufactured from austenitic stainless steel (typically 304 or 316 grade), essential for external applications, conservatories, coastal environments, or anywhere long-term durability in harsh conditions is paramount.

Who Uses Brad Nails?

- Carpenters and Joiners: Fixing architrave, skirting boards, dado rails, picture rails, decorative mouldings, and internal trim throughout residential and commercial properties

- Cabinet Makers: Installing face frames, attaching backing panels, securing decorative trim, assembling drawer components, and fixing beading on bespoke cabinetry

- Shop Fitters: Creating retail displays, fixing signage, installing decorative panelling, and assembling point-of-sale fixtures in commercial environments

- Picture Framers: Assembling delicate frames, securing mitred corners without splitting, and attaching backing boards on custom framing projects

- Furniture Makers: Attaching trim details, securing veneers, assembling lightweight furniture components, and fixing decorative elements on traditional and contemporary pieces

- General Builders: Installing internal trim, fixing beading, completing finishing touches on renovation projects, and securing temporary fixings during refurbishment work

- Staircase Installers: Securing balusters, fixing decorative nosings, attaching trim elements, and installing newel cap details on residential staircases

- DIY Enthusiasts: Home improvement projects requiring professional-quality finishing without visible fixings, including renovation work, furniture restoration, and decorative upgrades

How to Choose the Right Brad Nails

Gauge Selection: Opt for 18 gauge brad nails for most decorative trim, mouldings, and lightweight joinery applications where minimal splitting is crucial. Choose 16 gauge finish nails when working with heavier architrave, thicker skirting boards, or materials requiring greater holding power. Consider 23 gauge headless pins for ultra-delicate work on picture frames or veneer where even the smallest hole is unacceptable.

Length Considerations: Select brad nails that penetrate at least 15-20mm into the substrate for secure fixing. For typical architrave installation onto plasterboard over timber battens, 32-38mm brads work well. When fixing into solid timber, MDF, or hardwood, 40-50mm lengths provide optimal holding strength. Remember that longer nails require more driving force and may split thin materials if not positioned carefully.

Material and Coating: Use standard bright steel brad nails for interior applications in dry environments where cost efficiency is a priority. Specify galvanised brads for kitchens, bathrooms, utility rooms, or anywhere moisture may be present to prevent rust staining. Choose stainless steel variants for external applications, conservatories, or coastal locations where superior corrosion resistance justifies the premium cost.

Brand Compatibility: Ensure your chosen brad nails match your nailer's specifications regarding gauge, collation type, and length capacity. Most manufacturers including DeWalt, Bostitch, Stanley, Tacwise, and Arrow produce compatible fasteners, but always verify compatibility with your specific tool model before purchasing in bulk quantities to avoid costly mistakes.

Head Style and Finish: Standard brad nails feature a small cylindrical head that can be punched below the surface and filled. Brown-headed variants from brands like Arrow blend naturally with timber and reduce visibility before filling. For applications where no mark is acceptable, consider upgrading to headless micro pins instead of standard brads.

Popular Accessories

- Brad Nailers: Pneumatic or cordless tools from Makita, Milwaukee, DeWalt, Bosch, and Bostitch designed specifically to drive 16, 18, or 23 gauge brad nails and finish nails

- Air Compressors: Essential for pneumatic brad nailers, typically 6-50 litre capacity with sufficient CFM output for continuous operation throughout the working day

- Air Hoses and Fittings: Quality reinforced rubber or PVC hoses, quick-release couplers, pressure regulators, and inline lubricators for pneumatic nailer setups

- Battery Packs: Spare high-capacity lithium-ion batteries for cordless brad nailers to maintain productivity on site without interruption for charging

- Nail Punch Sets: For manually setting brad nail heads below the surface before filling, typically in 1mm, 1.5mm, and 2mm tip sizes

- Wood Filler: For concealing nail holes in exposed timber, available in various wood-tone shades including pine, oak, mahogany, and walnut

- Safety Glasses: Essential eye protection conforming to BS EN 166 when operating any nailer to guard against ricochets, wood splinters, or debris

- Hearing Protection: Ear defenders or foam plugs to protect against repetitive pneumatic nailer noise during extended projects on site

- Tool Belts and Pouches: For carrying brad nail strips, allowing quick reloading without returning to toolboxes or storage containers

Safety Information

Brad nailers are powerful tools that demand respect and proper safety protocols on every job. Always wear approved safety glasses conforming to BS EN 166 when operating any nailer, as ricochets, wood splinters, or nail deflection can cause serious eye injuries. Never disable safety mechanisms or operate the tool in bump-fire mode unless specifically appropriate for the task and permitted by your risk assessment.

Ensure your work area is clear of others before firing, and never point a loaded nailer at yourself or anyone else, even when not actively triggering. Be aware that brad nails can deflect when striking knots, embedded fasteners, or dense grain, potentially exiting the workpiece at unexpected angles. When working on construction sites, comply with HSE guidelines regarding nail gun use, and ensure all operators have received appropriate training and understand safe working practices.

Disconnect pneumatic nailers from air supply and remove battery packs from cordless models before clearing jams, performing maintenance, or making adjustments. Wear appropriate respiratory protection when working in enclosed spaces, as repeated nailer discharge can generate fine dust particles. Store brad nails in their original packaging in a dry location to prevent corrosion that could cause jamming or misfires during operation.

Frequently Asked Questions

What's the difference between brad nails and finish nails?

Brad nails are typically 18 gauge (1.25mm diameter) with very small heads, designed for delicate trim where minimal visibility is crucial. Finish nails are thicker (15-16 gauge) with slightly larger heads, providing greater holding power for heavier mouldings and architectural trim. Both leave small holes that can be filled, but brad nails are less likely to split thin or delicate materials like narrow beading or picture frame mouldings.

Can I use brad nails outdoors?

Standard bright steel brad nails will rust rapidly outdoors and cause unsightly staining. For external applications, always specify galvanised brad nails for moderate weather exposure or stainless steel variants for complete corrosion resistance in coastal or fully exposed locations. Even with appropriate fasteners, ensure your workpiece timber is suitable for external use and properly treated.

What length brad nail should I use for skirting boards?

For typical 18-20mm thick skirting fixed to plasterboard over timber battens, 40-50mm brad nails work well, ensuring at least 20-25mm penetration into the batten or wall substrate. When fixing directly into masonry or blockwork, consider using adhesive as the primary fixing method with brad nails providing temporary hold whilst the adhesive cures, as nails alone won't penetrate hard substrates effectively.

Are brad nails from different manufacturers interchangeable?

Generally yes, provided they match the gauge and collation angle specified for your nailer. Most 18 gauge brad nailers accept standard straight-collated strips from various manufacturers including DeWalt, Bostitch, Stanley, Tacwise, and Arrow. However, always verify compatibility with your specific tool model, particularly regarding length capacity, head style, and collation type to avoid jamming issues.

How do I prevent brad nails from splitting delicate mouldings?

Ensure you're using genuine 18 gauge brad nails rather than thicker finish nails. Pre-drilling pilot holes can help, though this defeats some of the speed advantage of nailers. Reduce your air pressure if using a pneumatic nailer (typically to 80-90 PSI), or lower the depth adjustment on cordless models. Position nails away from the workpiece ends where splitting is most likely, and consider 23 gauge headless pins for exceptionally delicate materials.

pta6327_181619.jpg?w=230&h=230&q=80)