ITL Socketry

Loading...

Loading...

End of content

Error - No more pages to load

ITL Socketry at Tooled-Up.com

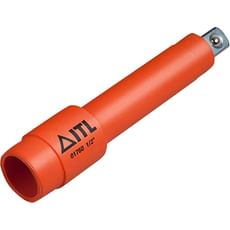

ITL (International Tools Limited) has established itself as a trusted name in professional socketry, delivering robust and reliable socket solutions for demanding trade applications. The brand's commitment to engineering excellence and practical design has made ITL Socketry a staple choice for professionals who require dependable tools that stand up to daily workshop and site use. From standard socket sets to specialised deep sockets and impact-rated variants, ITL's range combines affordability with the durability that UK tradespeople expect.

Tooled-Up.com stocks a comprehensive selection of ITL Socketry designed to meet the diverse needs of automotive technicians, mechanical engineers, and maintenance professionals. The range encompasses both metric and imperial sizing options, with chrome vanadium steel construction ensuring long-lasting performance even under high-torque applications. Whether you're working on automotive repairs, plant maintenance, or general mechanical assembly, ITL Socketry provides the precision fit and robust construction essential for professional results.

The ITL Socketry collection featuresSocket sets in various drive sizes including 1/4", 3/8", 1/2", and 3/4" configurations, alongside individual sockets for building custom tool kits. Each socket is manufactured to exacting standards with high-visibility size markings and corrosion-resistant finishes, making them suitable for both workshop and mobile applications where tools face exposure to challenging conditions.

Why Choose ITL Socketry?

ITL has built its reputation on delivering professional-grade tools at accessible price points without compromising on quality or performance. The brand's socketry range benefits from decades of manufacturing expertise, with each product engineered to withstand the rigours of commercial use. Chrome vanadium steel construction provides the perfect balance of hardness and toughness, reducing the risk of rounding or splitting under high torque loads.

The precision manufacturing process ensures accurate dimensional tolerances, giving ITL sockets the secure grip on fastener heads that prevents damage to both the socket and the workpiece. Heat-treated finishes enhance durability whilst providing corrosion resistance, extending tool life even in demanding environments. ITL's quality control processes ensure consistent performance across the range, giving tradespeople confidence in their investment.

Value represents another compelling reason to choose ITL Socketry. The brand offers professional performance at competitive prices, making it an excellent choice for both experienced tradespeople building comprehensive tool collections and those just entering the trades. The combination of reliable performance and accessible pricing has made ITL a popular choice throughout the UK trade sector.

Who Uses ITL Socketry?

- Automotive Technicians: Mechanics and vehicle technicians requiring reliable socket sets for engine work, suspension repairs, and general automotive maintenance

- Plant Maintenance Engineers: Industrial maintenance professionals working on machinery, conveyors, and production equipment

- Agricultural Engineers: Professionals maintaining and repairing farm machinery and equipment

- Manufacturing Assembly Workers: Production line workers and assemblers requiring consistent fastening tools

- General Engineering Workshops: Multi-discipline workshops needing versatile socketry for varied applications

- Mobile Mechanics: Service engineers requiring portable, reliable socket sets for on-site repairs

- DIY Enthusiasts: Serious home mechanics and hobbyists seeking professional-quality tools for personal projects

- Maintenance Contractors: Building services engineers and general maintenance operatives

Key Features of ITL Socketry

Chrome Vanadium Steel Construction: ITL sockets are manufactured from premium chrome vanadium steel, offering exceptional strength and durability for professional applications. The material's toughness resists cracking and splitting even under impact loads.

Precision Machining: Accurate dimensional tolerances ensure optimal engagement with fastener heads, reducing the risk of rounding and providing secure grip during high-torque applications. The precision fit maximises force transfer whilst minimising wear.

High-Visibility Size Markings: Each socket features clearly stamped size markings that remain legible throughout the tool's working life, enabling quick identification in busy workshop environments and reducing time spent searching for the correct size.

Corrosion-Resistant Finishes: Professional chrome plating provides excellent corrosion resistance whilst being easy to clean, maintaining appearance and functionality even after extensive use in challenging conditions.

Multiple Drive Configurations: Available in standard drive sizes from 1/4" through to 3/4", providing compatibility with existing ratchets, breaker bars, and torque wrenches across various applications and torque requirements.

Both Metric and Imperial Sizing: Comprehensive size ranges in both measurement systems ensure compatibility with British, European, and American equipment, making ITL Socketry suitable for diverse mechanical applications.

Popular ITL Socketry

The ITL range available from Tooled-Up encompasses several popular socket configurations suited to different professional requirements. Standard depth sockets in 1/4", 3/8", and 1/2" drive sizes form the core of most tool kits, providing versatile fastening solutions for general mechanical work. These are complemented by deep socket variants that offer extended reach for recessed fasteners and threaded rod applications.

Impact-rated ITL sockets feature thicker walls and black phosphate finishes, specifically engineered to withstand the forces generated by pneumatic and electric impact wrenches. These are essential for automotive workshops and assembly operations where speed and efficiency are paramount. Socket sets bundled with storage cases provide comprehensive solutions, offering organised collections spanning multiple sizes in convenient carrying systems.

Specialist formats including bi-hexagonal (12-point) profiles deliver enhanced access in restricted spaces, whilst hex (6-point) designs provide maximum grip for high-torque applications. The Tooled-Up ITL selection ensures professionals can source the specific socket configuration required for their particular trade requirements.

Safety and Compliance

ITL Socketry is manufactured to meet relevant British and European standards for hand tools, ensuring products deliver safe and reliable performance when used as intended. Users should always inspect sockets before use for signs of wear, cracking, or deformation, replacing damaged tools immediately to prevent injury or fastener damage.

Proper tool selection is essential for safe operation. Always use the correct drive size and socket depth for the application, and ensure sockets are fully seated on fastener heads before applying force. Never use standard sockets with impact tools – always select impact-rated variants for pneumatic or electric impact applications. Extension bars and universal joints should be used judiciously, as they can reduce torque transfer efficiency and increase the risk of socket slippage.

When working with socketry, appropriate personal protective equipment including safety glasses should be worn to protect against flying debris. Regular cleaning and proper storage extends tool life whilst maintaining safe operation. Following HSE guidelines for hand tool use and maintenance ensures ITL Socketry continues to perform safely throughout its working life.

Frequently Asked Questions

Are ITL sockets suitable for professional trade use?

Yes, ITL Socketry is designed for professional applications and is widely used across UK trade sectors. The chrome vanadium steel construction and precision manufacturing ensure durability and reliability for daily commercial use, making them suitable for workshops, garages, and industrial maintenance environments.

Can I use standard ITL sockets with impact wrenches?

No, standard chrome-plated sockets should never be used with impact tools as they can shatter under the repeated shock loads, posing serious safety risks. Always use impact-rated ITL sockets (typically with black phosphate finishes) when working with pneumatic or electric impact wrenches.

What's the difference between 6-point and 12-point ITL sockets?

Six-point (hex) sockets grip fastener heads at the flats, providing maximum torque transfer and reduced risk of rounding, making them ideal for high-torque applications or seized fasteners. Twelve-point (bi-hexagonal) sockets offer better access in restricted spaces where ratchet swing is limited, as they can engage the fastener at smaller rotation increments.

How should I maintain my ITL sockets to ensure long life?

After use, wipe sockets clean of oil, grease, and debris to prevent corrosion and maintain clear size markings. Store in organised socket rails or cases to prevent damage and ease selection. Regularly inspect for wear, cracks, or deformation, particularly around the drive square and socket opening. A light coating of tool oil helps prevent corrosion during storage.

Do ITL socket sets come with storage cases?

Many ITL socket sets include storage cases or socket rails for organised keeping and easy transport. Individual sockets are also available, allowing professionals to build custom collections or replace specific sizes as needed. Check individual product specifications for included storage solutions.