Sia Abrasives Power Tool Accessories

Loading...

Loading...

End of content

Error - No more pages to load

Sia Abrasives Power Tool Accessories at Tooled-Up.com

Sia Abrasives has earned its reputation as one of Europe's leading manufacturers of premium abrasive solutions, delivering consistently high-quality power tool accessories trusted by professionals across the UK and beyond. With over 100 years of Swiss engineering excellence, Sia Abrasives combines cutting-edge research and development with traditional craftsmanship to produce power tool accessories that deliver exceptional performance, longevity, and value. From sanding discs and grinding wheels to polishing pads and specialist abrasive products, Sia Abrasives power tool accessories represent the perfect balance between innovation and reliability.

The comprehensive selection of Sia Abrasives power tool accessories available from Tooled-Up.com caters to virtually every surface preparation, finishing, and material removal application imaginable. Whether you're working with wood, metal, plastics, composites, or painted surfaces, Sia Abrasives has engineered specialist solutions designed to maximise efficiency whilst minimising dust and material waste. Their product range encompasses everything from heavy-duty grinding applications through to ultra-fine finishing work, ensuring tradespeople have access to the right tool accessory for every stage of their project.

What truly distinguishes Sia Abrasives from competitors is their commitment to innovation in abrasive technology. The brand continuously invests in research to develop new grain compositions, bonding agents, and backing materials that enhance cutting performance, extend product life, and improve user comfort. This dedication to advancement ensures that professionals using Sia Abrasives power tool accessories benefit from the latest developments in abrasive science, translating to faster work completion, superior surface finishes, and reduced accessory costs over time.

Why Choose Sia Abrasives Power Tool Accessories?

Sia Abrasives power tool accessories are engineered to withstand the demanding conditions of professional use, where reliability and consistency are non-negotiable. The brand's Swiss manufacturing heritage ensures rigorous quality control at every production stage, resulting in accessories that perform predictably from first use to last. This consistency means tradespeople can rely on Sia Abrasives products to deliver uniform results across entire projects, eliminating the frustration of variable performance that can occur with inferior alternatives.

The longevity of Sia Abrasives products represents genuine value for money. Whilst premium-priced compared to budget options, Sia accessories typically outlast competing products by significant margins, reducing the frequency of accessory changes and minimising downtime. This extended service life is achieved through advanced grain technology and superior bonding systems that resist premature wear, maintaining cutting efficiency throughout the product's lifespan. For busy professionals, this translates to fewer interruptions, lower consumable costs, and improved project profitability.

Environmental responsibility is increasingly important to modern tradespeople, and Sia Abrasives addresses this through sustainable manufacturing practices and product designs that minimise waste. Their dust extraction-optimised accessories work efficiently with power tool vacuum systems, creating healthier working environments whilst ensuring compliance with HSE workplace exposure limits. This commitment to user wellbeing and environmental stewardship makes Sia Abrasives an ethical choice for conscientious professionals.

Who Uses Sia Abrasives Power Tool Accessories?

- Automotive body shops and refinishers requiring premium sanding and polishing solutions for paint preparation and finishing work

- Cabinet makers and joiners who demand consistent surface preparation across hardwoods, softwoods, and manufactured boards

- Metal fabricators and welders needing reliable grinding and finishing accessories for steel, stainless steel, and aluminium

- Shopfitters and commercial refurbishment contractors working across multiple substrates and requiring versatile abrasive solutions

- Boat builders and marine engineers who value corrosion-resistant accessories suitable for demanding marine environments

- Furniture restorers and antique specialists requiring precision finishing accessories for delicate restoration work

- Maintenance engineers and facilities managers seeking durable accessories for equipment servicing and site maintenance

- Serious DIY enthusiasts who appreciate professional-grade performance for home workshop projects

Key Features of Sia Abrasives Power Tool Accessories

Advanced Grain Technology: Sia Abrasives employs proprietary grain formulations including ceramic, zirconia, and aluminium oxide variants, each optimised for specific materials and applications. These engineered grains self-sharpen during use, maintaining aggressive cutting action and preventing the glazing that reduces effectiveness in conventional abrasives.

Superior Backing Materials: The backing materials used in Sia Abrasives accessories are selected for optimal flexibility, tear resistance, and heat dissipation. Whether cloth, paper, film, or fibre-reinforced options, each backing is matched to the application demands, ensuring accessories maintain their integrity under professional working loads.

Dust Extraction Optimisation: Many Sia Abrasives products feature precisely engineered hole patterns and open-coat designs that facilitate superior dust extraction when used with appropriate power tool vacuum systems. This reduces airborne particulates, maintains accessory performance, and creates healthier working environments compliant with COSHH regulations.

Anti-Clogging Technology: Specialist stearate coatings and open-coat grain distributions prevent material build-up on abrasive surfaces, particularly when working with softwoods, paints, and resins that typically cause premature clogging. This extends accessory life and maintains consistent cutting performance throughout the product's service period.

Popular Sia Abrasives Power Tool Accessories

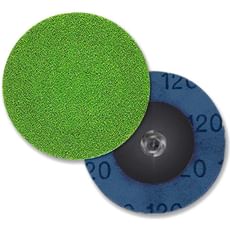

Sanding Discs: Available in numerous diameters, grit grades, and attachment systems including hook-and-loop, adhesive-backed, and hole-punched variants for random orbital sanders, palm sanders, and disc sanders. Sia's sanding discs are renowned for their durability and consistent scratch patterns.

Grinding Wheels and Discs: Heavy-duty accessories for angle grinders and bench grinders, engineered for metal removal, weld preparation, and surface cleaning. These products balance aggressive material removal with controlled stock removal rates suitable for precision work.

Abrasive Belts: Continuous abrasive belts for belt sanders in various widths and lengths, offering excellent performance across wood and metal applications. Sia's belt construction ensures resistance to edge wear and tracking problems common with lesser products.

Polishing Pads and Compounds: Specialist finishing accessories for achieving professional surface finishes on paintwork, metal, and composite materials. These products are particularly valued in automotive refinishing and high-end furniture production.

Safety and Compliance

All Sia Abrasives power tool accessories supplied through Tooled-Up comply with relevant UK and European safety standards, including EN 13743 for flexible abrasives and EN 12413 for bonded abrasive products. When using any abrasive accessory, appropriate personal protective equipment including safety glasses, dust masks or respirators, and hearing protection should always be worn. Ensure power tools are suitable for the accessory's maximum operating speed, and never exceed the rated RPM marked on grinding wheels and cut-off discs.

Proper dust extraction is essential when using abrasive accessories, both for maintaining product performance and protecting user health. The HSE provides clear guidance on workplace exposure limits for various dusts, and Sia Abrasives products work effectively with extraction systems to help maintain compliance. Always ensure adequate ventilation when working indoors, and consider additional respiratory protection when working with materials that produce hazardous dusts, particularly hardwoods, MDF, and certain composites.

Frequently Asked Questions

What makes Sia Abrasives power tool accessories better than budget alternatives?

Sia Abrasives products feature advanced grain technology, superior backing materials, and precision manufacturing that delivers longer service life, more consistent performance, and better surface finishes. Whilst initially more expensive, they typically prove more economical over time due to extended longevity and reduced accessory changes, alongside delivering professional-quality results that budget products cannot match.

Are Sia Abrasives accessories compatible with all power tool brands?

Yes, Sia Abrasives manufactures accessories in industry-standard sizes and attachment formats compatible with power tools from all major manufacturers. Whether you're using Bosch, Makita, DeWalt, Festool, or any other brand, you'll find compatible Sia accessories. Always verify the accessory diameter, arbor size, and maximum operating speed match your tool's specifications before use.

Which grit grade should I choose for my application?

Coarse grits (40-80) are suited to heavy material removal and initial surface preparation. Medium grits (100-150) handle general sanding and preparation before finishing. Fine grits (180-320) are used for final surface preparation before coating. Very fine grits (400+) achieve polishing and ultra-smooth finishes. For best results, progress through grades systematically rather than jumping from coarse directly to fine.

How can I maximise the life of Sia Abrasives accessories?

Use appropriate pressure—excessive force generates heat and premature wear whilst insufficient pressure reduces efficiency. Ensure proper dust extraction to prevent clogging. Match the abrasive grade to your material and application rather than using one grade for everything. Store accessories flat in dry conditions away from extreme temperatures, and inspect for damage before use.

Are Sia Abrasives products suitable for use with extraction systems?

Absolutely. Many Sia Abrasives accessories are specifically designed with dust extraction in mind, featuring hole patterns and open-coat designs that work efficiently with power tool vacuum systems. This not only creates healthier working environments but also extends accessory life by preventing dust build-up that causes premature clogging and reduces cutting efficiency.