Spear and Jackson Plastering Trowels

Loading...

Loading...

End of content

Error - No more pages to load

Spear and Jackson Plastering Trowels at Tooled-Up.com

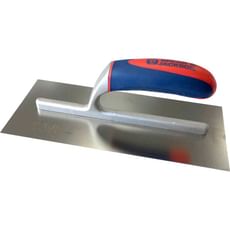

Spear and Jackson has been a cornerstone of British tool manufacturing since 1760, and their plastering trowels exemplify over 260 years of metalworking expertise. The Spear and Jackson plastering trowel range represents precision-engineered tools designed specifically for the demanding requirements of professional plasterers and skilled tradespeople across the UK. Each trowel is manufactured to exacting standards, combining traditional craftsmanship with modern metallurgy to deliver tools that perform reliably day after day on site.

From finishing trowels to laying-on trowels and specialist shapes, the Spear and Jackson collection at Tooled-Up.com caters to every plastering application. Whether you're skimming walls, applying render, or finishing decorative plasterwork, these trowels are engineered to provide the perfect balance of flexibility, strength, and control. The brand's commitment to quality ensures that each blade is carefully tempered and finished to provide the ideal surface texture for professional results.

Professional plasterers trust Spear and Jackson plastering trowels for their consistent performance and durability. Available from Tooled-Up, these tools feature ergonomically designed handles and perfectly balanced blades that reduce fatigue during extended use, making them ideal for both commercial projects and demanding domestic applications.

Why Choose Spear and Jackson Plastering Trowels?

Spear and Jackson's reputation in the plastering trade is built on decades of proven performance on UK building sites. Their plastering trowels are manufactured using high-carbon steel that's specifically tempered to achieve the optimal combination of rigidity and flexibility – essential characteristics for achieving smooth, professional finishes. The blades are precision-ground to ensure uniform thickness and perfect flatness straight from the box, eliminating the need for extensive breaking-in periods.

The brand's attention to detail extends to every aspect of trowel construction. Handle designs incorporate soft-grip materials that provide comfort during prolonged use whilst maintaining excellent control, even when working with wet materials. The mounting system ensures secure blade attachment that withstands the twisting forces encountered during troweling operations. Many professional plasterers appreciate that Spear and Jackson trowels maintain their shape and flexibility throughout their working life, unlike cheaper alternatives that can develop warps or lose their temper.

Quality control standards at Spear and Jackson ensure consistency across their entire range. Each trowel undergoes rigorous inspection to verify blade flatness, edge finish, and handle integrity before leaving the factory. This commitment to manufacturing excellence means tradespeople can rely on consistent performance whether they're purchasing their first trowel or replacing a well-used favourite.

Who Uses Spear and Jackson Plastering Trowels?

- Professional plasterers working on commercial and domestic projects

- Rendering specialists applying external wall finishes

- Dry liners finishing plasterboard installations

- Restoration specialists working with traditional lime plasters

- General builders requiring reliable plastering tools for varied projects

- Maintenance teams conducting repair and refurbishment work

- Serious DIY enthusiasts undertaking quality home improvement projects

- Apprentice plasterers investing in professional-grade tools for their careers

Key Features of Spear and Jackson Plastering Trowels

Spear and Jackson plastering trowels incorporate several distinctive features that enhance performance and longevity. The high-carbon steel blades are precisely tempered to achieve the perfect balance between stiffness for material control and flexibility for smooth finishing strokes. Blade edges are carefully rounded and polished to prevent scoring or dragging, whilst the surface finish is optimised to release plaster cleanly without excessive adhesion.

Handle design represents a critical element of Spear and Jackson's engineering philosophy. Their plastering trowel handles feature ergonomic shaping that distributes pressure evenly across the palm, reducing fatigue and improving control during extended plastering sessions. Soft-grip materials provide secure purchase even when wet, whilst the handle angle is optimised for natural wrist positioning during typical troweling motions.

The mounting system that secures blade to handle is engineered for maximum strength and durability. Spear and Jackson employs robust attachment methods that prevent handle rotation or loosening, even under the substantial forces generated during professional plastering work. This attention to structural integrity ensures that their trowels remain reliable tools throughout years of demanding site use.

Popular Spear and Jackson Plastering Trowels

The Spear and Jackson plastering trowel range encompasses various blade sizes and shapes to suit different applications. Standard finishing trowels are available in sizes ranging from 280mm to 450mm, allowing plasterers to select the appropriate size for their working style and the scale of surfaces being finished. Pre-worn finishing trowels offer blades that have been factory-processed to simulate the characteristics of a broken-in tool, providing experienced plasterers with immediate optimal performance.

Laying-on trowels feature slightly thicker, more rigid blades designed for applying and spreading base coat materials, whilst the Spear and Jackson range also includes specialist patterns such as bucket trowels, gauging trowels, and corner trowels. Each design addresses specific plastering requirements, ensuring that professionals have access to the precise tool needed for any situation they encounter on site.

Safety and Compliance

Whilst plastering trowels are hand tools without electrical components, proper usage remains important for workplace safety. Users should inspect trowels before each use to ensure handles are secure and blades show no signs of damage or excessive wear. When working at height or on scaffolding, tools should be secured to prevent drops that could cause injury to workers below, in accordance with HSE guidelines for site safety.

Spear and Jackson manufactures their plastering trowels to meet relevant British and European standards for hand tools. Proper tool maintenance, including cleaning after use and appropriate storage, helps maintain performance and prevents premature deterioration. Plasterers should wear appropriate personal protective equipment, including dust masks when sanding, safety glasses, and protective footwear as required by site regulations.

Frequently Asked Questions

What size Spear and Jackson plastering trowel should I choose?

Trowel size depends on your experience level and the work being undertaken. Beginners often find 350mm trowels easier to control, whilst experienced plasterers may prefer 400mm or 450mm blades for covering large areas efficiently. For small repair work or tight spaces, smaller gauging trowels around 180mm-250mm are more appropriate.

Do Spear and Jackson plastering trowels require breaking in?

Traditional finishing trowels benefit from a breaking-in period where the blade edges become slightly rounded through use, making them easier to achieve smooth finishes. However, Spear and Jackson also offers pre-worn trowels that have been factory-processed to provide immediate optimal performance without requiring this break-in period.

How should I maintain my Spear and Jackson plastering trowel?

Clean your trowel thoroughly after each use, removing all plaster residue before it hardens. Wipe the blade with a slightly oily cloth to prevent rust formation during storage. Check the handle mounting regularly and tighten if any movement develops. Store trowels in a dry location to prevent corrosion.

What's the difference between a finishing trowel and a laying-on trowel?

Finishing trowels feature thinner, more flexible blades designed for applying and smoothing final coat plaster to achieve polished surfaces. Laying-on trowels have thicker, more rigid blades suited to applying and spreading thicker base coat materials. Spear and Jackson manufactures both types to professional specifications.

Are Spear and Jackson plastering trowels suitable for both gypsum and lime plasters?

Yes, Spear and Jackson plastering trowels perform excellently with all common plastering materials including gypsum-based finishing plasters, lime plasters, and cement-based renders. The stainless steel and properly tempered carbon steel options resist corrosion from various plaster chemistries, making them versatile tools for diverse plastering applications.