Extension Bars

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Extension Bars

Extension bars are indispensable socket accessories that enable you to reach fasteners in deep, recessed, or awkward positions where a standard ratchet handle alone simply won't fit. These precision-engineered tools effectively bridge the gap between your ratchet or torque wrench and the socket, extending your reach by anywhere from 50mm to 500mm or more. Whether you're working on engine components buried deep in the bay, accessing chassis bolts underneath a vehicle, or tackling pipework in confined spaces, the right extension bar transforms an impossible job into a straightforward task.

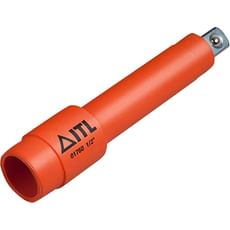

Available in the three standard drive sizes—1/4" drive for light-duty precision work, 3/8" drive for general mechanical applications, and 1/2" drive for heavy-duty tasks requiring substantial torque—extension bars come in various configurations to suit different requirements. The selection at Tooled-Up.com includes standard chrome-plated extensions for everyday use, wobble extensions with flexible heads for angled access, impact-rated extensions designed specifically for use with impact wrenches, and even VDE insulated extensions for electrical work near live components. Leading manufacturers including Draper, Bahco, Facom, Elora, and Blue Spot produce extension bars to exacting standards, ensuring reliable performance and longevity in demanding trade environments.

Quality extension bars are manufactured from chrome vanadium steel or chrome molybdenum steel, providing the strength to withstand high torque loads without flexing or snapping. The precision-machined drive ends ensure a secure connection to both ratchet and socket, minimising the risk of rounded fasteners or tool slippage. Many professionals invest in extension bar sets, which provide a range of lengths in a single package, ensuring you always have the right reach for the job at hand. Chrome finishes—whether polished or satin—offer excellent corrosion resistance for workshop and site use alike.

Jargon Buster

- Drive Size: The square connection size that fits into sockets and onto ratchets, measured in inches. Common sizes are 1/4", 3/8", and 1/2" drive, with each suited to different torque requirements and socket sizes.

- Wobble Extension: An extension bar featuring a spring-loaded ball bearing mechanism at one or both ends, allowing the socket to operate at an angle (typically up to 15 degrees) to the drive—ideal for accessing fasteners that aren't perfectly aligned with your ratchet position.

- Impact Extension: A heavy-duty extension bar specifically engineered to withstand the hammering action of impact wrenches and impact drivers, manufactured from tougher materials with reinforced drive ends and typically finished in black phosphate or black oxide.

- VDE Insulated: Extensions that meet German VDE standards for electrical safety, featuring insulation rated to protect users working on or near live electrical components up to 1000V AC or 1500V DC—essential for automotive electricians and electrical contractors.

- Chrome Vanadium (Cr-V): A steel alloy combining chromium and vanadium, offering excellent strength, durability, and corrosion resistance—the standard material for quality socket accessories and hand tools.

- Torque Stick: A specialised extension bar designed to flex at a predetermined torque value, commonly used in tyre-fitting applications to prevent over-tightening of wheel nuts when using impact wrenches.

Who Uses Extension Bars?

Extension bars are indispensable tools across numerous trades and industries:

- Motor mechanics and automotive technicians accessing engine bay components, suspension bolts, and exhaust systems

- Mobile mechanics and vehicle recovery specialists working on roadside repairs with limited access

- Plant fitters and agricultural engineers maintaining heavy machinery and farm equipment

- Motorcycle mechanics reaching recessed fasteners on bikes, ATVs, and scooters

- Plumbers and heating engineers working on pipework in confined spaces beneath boilers or behind radiators

- Electricians and electrical contractors (using VDE insulated extensions) working on distribution boards and consumer units

- Plant maintenance engineers servicing industrial equipment and production machinery

- Bicycle mechanics requiring precision access with 1/4" drive tools

- DIY enthusiasts and home mechanics tackling repairs and maintenance projects

- HVAC engineers installing and servicing air conditioning and ventilation systems

- Marine engineers working on boat engines and marine equipment

How to Choose the Right Extension Bars

Drive Size Compatibility: Ensure your extension bar matches your existing socket set and ratchet. A 1/4" drive is perfect for smaller fasteners and delicate work, 3/8" drive handles most general automotive and mechanical tasks, whilst 1/2" drive is necessary for heavy-duty applications requiring higher torque values.

Length Requirements: Consider the typical depth of access you need. Common lengths include 50mm, 75mm, 100mm, 150mm, 250mm, and 500mm. Many professionals opt for a set containing three to five different lengths, providing versatility across various applications. Remember that longer extensions can introduce flex under high torque, so use the shortest extension that reaches comfortably.

Material and Finish: Chrome vanadium steel with either polished chrome or satin chrome finish offers the best combination of strength and corrosion resistance for general use. Look for drop-forged construction rather than cast steel for superior durability. Impact-rated extensions with black oxide or phosphate finishes are essential if you'll be using air or cordless impact wrenches.

Wobble vs Standard: Wobble extensions provide flexibility when working at angles but may introduce slight play in the connection. Standard rigid extensions offer more precise control and are better suited to high-torque applications. Consider having both types in your toolkit for maximum versatility.

Special Requirements: If you work on or near electrical installations, VDE insulated extensions rated to 1000V are a legal requirement under HSE guidelines. Torque sticks are invaluable for tyre-fitting work to protect wheel studs and achieve consistent tightening without over-torquing.

Brand Quality: Established brands like Bahco, Draper, Facom, and Elora offer warranties and consistent manufacturing standards. Professional-grade extensions may cost more initially but will outlast budget alternatives many times over in demanding trade use, making them a sound investment for tradespeople.

Popular Accessories

- Socket sets in matching drive sizes (1/4", 3/8", or 1/2" drive) from brands like Draper and Bahco

- Ratchet handles including quick-release and flex-head models

- Universal joints for even greater angular flexibility beyond wobble extensions

- Sliding T-bars and breaker bars for additional leverage on stubborn fasteners

- Impact sockets designed to work safely with impact-rated extensions

- Torque wrenches for precision tightening to manufacturer specifications

- Socket rails and organisers for workshop and mobile storage

- Extension bar adapters to convert between different drive sizes

- Tool rolls and socket cases for transporting extensions and sockets to site work

- Magnetic bit holders and socket holders for easy access

Safety Information

Electrical Work: When working on or near live electrical components, only use VDE insulated extension bars rated to appropriate voltage levels. Standard chrome extensions conduct electricity and pose serious risk of electric shock. Always follow HSE guidelines and ensure installations are properly isolated wherever possible.

Impact Tool Use: Never use standard chrome extensions with impact wrenches or impact drivers. The sudden rotational forces can cause standard extensions to shatter, creating dangerous flying debris. Always use impact-rated extensions with black oxide or phosphate finish for pneumatic or cordless impact tools.

Torque Limitations: Longer extensions can flex under high torque, potentially leading to inaccurate torque readings when using a torque wrench or causing fastener damage. Use the shortest extension that provides adequate reach, and if using a torque wrench with an extension, be aware that very long extensions may require torque calculation adjustments.

Wear and Inspection: Regularly inspect extension bars for wear, particularly at the drive ends where rounded corners indicate damage. Worn extensions can slip under load, potentially causing injury or damaging fasteners. Replace any extension showing signs of cracking, bending, or significant wear.

Proper Connection: Ensure extensions are fully seated onto the ratchet drive and that sockets are properly engaged on the extension. Partial connections can lead to tool separation under load, risking injury and fastener damage.

Frequently Asked Questions

Can I use multiple extension bars connected together for extra reach?

Whilst it's physically possible to connect multiple extensions, this practice isn't recommended for several reasons. Each additional connection point introduces potential flex and reduces torque accuracy. The assembly becomes increasingly unstable and can separate under load. If you regularly need extended reach, invest in a longer single-piece extension bar which will provide much better rigidity and control.

What's the difference between polished chrome and satin chrome finish?

Both finishes offer excellent corrosion resistance, but polished chrome has a mirror-like finish that's easier to clean and shows less wear visually, making it popular for professional tool kits. Satin chrome has a brushed appearance that's slightly less reflective and can hide minor scratches better. Performance-wise, there's negligible difference—the choice often comes down to personal preference and matching existing tools.

Do I need different extension bars for my cordless impact wrench?

Yes, absolutely. Cordless impact wrenches generate sudden rotational impacts that standard chrome extensions aren't designed to handle. You must use impact-rated extension bars, which are manufactured from tougher steel and finished in black oxide or black phosphate. These are specifically engineered to absorb the hammering action without fracturing. Using standard extensions with impact tools is dangerous and will likely result in tool failure.

How do wobble extensions work and when should I use them?

Wobble extensions feature a spring-loaded ball bearing mechanism at one or both ends that allows the socket to articulate at an angle (typically up to 15 degrees) whilst maintaining drive engagement. They're invaluable when fasteners aren't perfectly aligned with your working position or in confined spaces where you can't position your ratchet directly in line. However, for maximum torque applications or precision torque wrench work, a rigid extension provides better accuracy and control.

Are cheaper extension bars a false economy?

Generally, yes—particularly for trade use. Budget extensions are often manufactured from inferior steel that can flex, wear quickly, or even snap under normal working loads. The drive ends may be imprecisely machined, leading to poor socket fit and rounded fasteners. Tooled-Up stocks quality brands like Bahco, Facom, Draper, and Elora that use superior materials, precision manufacturing, and offer warranties. For professional tradespeople, the reliability and longevity of quality extensions far outweigh the modest additional investment.