Jigsaw Blades

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Jigsaw Blades

Jigsaw blades are essential consumable accessories that directly influence the cutting performance, precision and finish quality of your jigsaw. Whether you're cutting intricate curves in laminate worktops, making plunge cuts in floorboards, or slicing through sheet metal, selecting the correct blade for the material and application is fundamental to achieving professional results. The range at Tooled-Up includes an extensive selection of jigsaw blades from Bosch Professional and other leading manufacturers, designed to tackle everything from softwood and hardwood to metal, plastics, ceramics and composite materials.

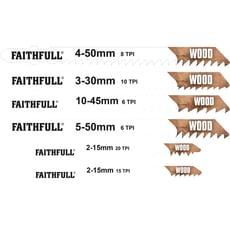

Modern jigsaw blades come in various tooth configurations, materials and shank types to suit different jigsaws and cutting requirements. High Carbon Steel (HCS) blades are ideal for softwood and general-purpose work, whilst High Speed Steel (HSS) and Bi-Metal blades offer the durability needed for metal cutting applications. For the most demanding tasks involving abrasive materials like tiles, fibreglass or cement board, carbide-tipped blades provide exceptional longevity. Understanding the differences between blade types, tooth patterns and TPI (teeth per inch) ratings will help you achieve cleaner cuts, reduce splintering and extend blade life across your projects.

Tooled-Up.com stocks individual specialist blades for specific tasks, convenient multi-blade sets covering various materials, and value-packed assortments that keep your toolbox well-stocked. Whether you're a professional joiner requiring precision blades for fine furniture work, a kitchen fitter cutting laminate worktops, or a maintenance engineer tackling mixed materials on site, you'll find the right jigsaw blade to match your requirements and budget.

Jargon Buster

- TPI (Teeth Per Inch): The number of teeth along one inch of the blade. Higher TPI (10-20) produces smoother, slower cuts ideal for metals and fine work, whilst lower TPI (3-8) cuts faster through wood but leaves a rougher finish.

- HCS (High Carbon Steel): Flexible blade material suitable for cutting softwood, hardwood, chipboard and plastics. These blades are economical but wear more quickly when cutting harder materials.

- HSS (High Speed Steel): Harder, more heat-resistant material designed for cutting ferrous and non-ferrous metals, including sheet steel, aluminium and copper pipe.

- Bi-Metal Blades: Combining an HSS cutting edge with a flexible HCS body, these versatile blades offer durability for metal cutting with the flexibility to resist breaking, making them ideal for demanding professional use.

- T-Shank vs U-Shank: The two main blade fitting types. T-shank (tang shank) is the modern universal standard offering tool-free blade changes, whilst U-shank (universal shank) is found on older jigsaw models and requires a grub screw or allen key.

- Reverse Tooth Blades: Feature teeth pointing downwards to cut on the downstroke, minimising surface splintering on the top face—essential for laminate worktops, veneered panels and other visible surfaces.

Who Uses Jigsaw Blades?

- Joiners and Carpenters: For cutting curves, creating cut-outs in worktops, and precision woodworking tasks

- Kitchen Fitters: Cutting sink apertures and hob openings in laminate and solid wood worktops

- Flooring Specialists: Trimming laminate, engineered wood and vinyl flooring around architraves and pipes

- Shopfitters and Retail Installers: Creating custom shapes and cut-outs in display materials and fixtures

- Electricians and Plumbers: Cutting access holes in floorboards, plasterboard and sheet materials for cable runs and pipework

- Maintenance Engineers: General site work requiring cuts through diverse materials from timber to thin metal

- Signmakers: Cutting intricate shapes in plastics, acrylics and composite materials

- DIY Enthusiasts: Home improvement projects involving furniture making, shelving and general woodworking

- Metal Fabricators: Cutting sheet metal, profiles and thin-gauge steel components

How to Choose the Right Jigsaw Blades

Material Being Cut: This is your primary consideration. Wood-cutting blades typically use HCS construction with larger, more aggressive teeth, whilst metal-cutting blades require HSS or Bi-Metal construction with finer teeth. For abrasive materials like tiles, fibreglass or cement board, carbide-grit or diamond-coated blades are essential. Multi-material blades offer versatility for varied work but may compromise on specialist performance.

Blade Length: Standard jigsaw blades range from 75mm to 150mm in length. Choose a blade at least 10-15mm longer than the thickness of your material to ensure the teeth fully penetrate during cutting. Longer blades (130-150mm) are necessary for cutting thick timber beams or worktops, whilst shorter blades provide better control for thin materials.

Teeth Per Inch (TPI): Lower TPI (3-6) offers fast, aggressive cutting in softwood and chipboard but leaves rougher edges. Medium TPI (6-10) provides a balance for general hardwood and softwood work. High TPI (10-20+) delivers slower, cleaner cuts essential for metals, plastics and when finish quality matters more than speed.

Tooth Configuration: Standard set teeth handle most general cutting. Reverse tooth or down-cut blades minimise top-surface splintering on laminates and veneers. Side-set teeth with wider kerf help prevent binding in green or resinous timber. Milled or ground teeth provide cleaner cuts than stamped teeth on premium blades.

Shank Type Compatibility: Modern jigsaws predominantly use T-shank fittings for tool-free blade changes, whilst older models may require U-shank blades. Always verify your jigsaw's shank type before purchasing—using the wrong fitting can be dangerous and won't secure properly. Most professional brands like Bosch, Makita, DeWalt and Festool now exclusively use T-shank systems.

Application-Specific Blades: Consider specialist blades for particular tasks: anti-splinter blades for visible surfaces, plunge-cut blades with tapered backs for starting cuts without pilot holes, flush-cutting blades for cutting close to walls, and scrolling blades with narrow profiles for tight radius curves.

Popular Accessories

- Anti-Splinter Inserts: Transparent plastic guards that fit around the blade to support wood fibres and prevent tear-out on the top surface

- Cutting Guides and Fences: Parallel guides and circle-cutting attachments for accurate straight-line and curved cuts

- Blade Storage Cases: Organised storage solutions to protect blades and keep different types easily identifiable

- Lubricants and Cutting Fluids: Specialist cutting waxes and lubricants to reduce friction and heat when cutting metals

- Dust Extraction Attachments: Hose adapters to connect your jigsaw to workshop vacuum systems for cleaner working

- Non-Slip Mats: Anti-slip workbench mats to secure workpieces during cutting

- Jigsaw Tables: Conversion accessories that mount your jigsaw underneath a work surface for stationary operation

Safety Information

Always ensure your jigsaw is disconnected from the 240v power supply or the battery is removed before changing blades. Wear appropriate eye protection when operating jigsaws, as the cutting action can throw debris upwards towards your face. Dust masks or respiratory protection should be worn when cutting materials that produce harmful dust, particularly MDF, treated timber or composite materials—refer to COSHH guidelines for your workplace.

Inspect blades before fitting and discard any that show signs of damage, missing teeth or cracks, as blade failure during operation can cause injury. Never force a worn blade to continue cutting—dull blades require excessive pressure, increasing the risk of the tool slipping or binding. When cutting sheet metal or materials that produce hot swarf, wear appropriate gloves when handling freshly cut edges and allow blades to cool before touching them.

Ensure workpieces are properly secured with clamps or a vice before cutting, and maintain firm control of the jigsaw with both hands where possible. Be aware of the blade's exit point and ensure nothing is positioned beneath that could be damaged or cause dangerous kickback. Follow all HSE guidance for power tool operation in professional environments, and ensure adequate training and supervision for less experienced operators.

Frequently Asked Questions

How often should I replace jigsaw blades?

Replace blades as soon as you notice reduced cutting performance, excessive vibration, burning of the material, or visible damage to teeth. A sharp blade requires minimal pressure and produces clean cuts—if you're forcing the tool or noticing rough edges, it's time for a new blade. Professional tradespeople working daily may replace blades after just a few hours of cutting harder materials, whilst occasional DIY users might get months of use from a blade cutting softwood.

What does the numbering system on Bosch jigsaw blades mean?

Bosch uses a systematic numbering code on their blades. The letter indicates shank type (T = T-shank), the first number indicates blade length (1 = short up to 75mm, 3 = medium up to 150mm, 5 = long over 150mm), the second number indicates tooth size (1 = fine, 7 = coarse), and the third number indicates tooth configuration. Additional letters at the end indicate material suitability: F for metal, HM for special applications, O for wood and other materials.

Can I use the same blade for different materials?

Whilst multi-material blades exist and work reasonably well across wood, plastics and thin metals, you'll achieve better results, faster cuts and longer blade life by using material-specific blades. Wood blades used on metal will quickly dull and may overheat, whilst metal blades in wood cut unnecessarily slowly. For professional work demanding quality results, always select the appropriate blade for your material.

Why does my jigsaw blade keep breaking?

Blade breakage typically results from forcing the tool too hard, twisting the blade during curved cuts (particularly with thick materials), using worn blades, or cutting material that's too thick for the blade length. Ensure you're using the correct blade type for your material, allow the tool to cut at its own pace without forcing, and support both sides of the cut line to prevent pinching. Cheaper blades may also be more brittle than professional-grade alternatives.

How can I reduce splintering when cutting laminate worktops?

Use a reverse-tooth (down-cut) blade specifically designed for laminate, which cuts on the downstroke to protect the top surface. Apply masking tape along your cut line to support the laminate surface, and ensure your blade is sharp—dull blades tear rather than cut cleanly. Cutting from the underside of the worktop also helps, as any splintering occurs on the less visible face. An anti-splinter insert fitted to your jigsaw provides additional support around the blade.