Safety Signs

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Safety Signs

Safety signs are essential visual communication tools that protect workers, visitors, and the general public by clearly identifying hazards, providing mandatory instructions, and indicating emergency equipment locations. From construction sites and warehouses to factories and commercial premises, properly displayed safety signage helps comply with the Health and Safety (Safety Signs and Signals) Regulations 1996 and creates a safer working environment. These signs use standardised colours, symbols, and pictograms recognised across the UK and Europe, ensuring that safety messages are understood quickly and universally, even in multilingual workplaces.

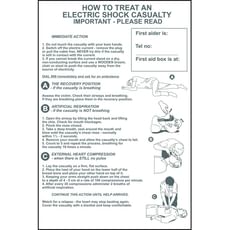

The safety sign range at Tooled-Up.com encompasses warning signs that alert people to specific hazards like electrical dangers, slippery surfaces, or overhead loads; mandatory signs that communicate required actions such as wearing PPE or maintaining hygiene protocols; prohibition signs that clearly state what must not be done in certain areas; and emergency information signs that guide people to exits, first aid stations, and assembly points. Modern safety signs are manufactured from durable materials including rigid plastic, self-adhesive vinyl, and aluminium, ensuring longevity in demanding industrial and outdoor environments.

Compliance with HSE guidance requires employers to assess their workplace, identify where safety signs are necessary, and ensure signage remains visible, legible, and relevant. Whether marking hazardous substances under COSHH regulations, identifying 240v electrical equipment risks, or designating safe routes through busy work areas, appropriate safety signage forms a crucial part of any comprehensive health and safety strategy. Tooled-Up stocks both standard pre-printed signs meeting BS EN ISO 7010 specifications and customisable options for site-specific requirements.

Jargon Buster

- BS EN ISO 7010: The British and European standard that specifies registered safety signs for accident prevention, fire protection, hazard warnings, and emergency evacuation. Signs complying with this standard use consistent colours, shapes, and symbols recognised internationally.

- Pictogram: A standardised graphic symbol used on safety signs to convey information quickly without relying on text, particularly valuable in multilingual workplaces or when immediate hazard recognition is critical.

- Prohibition Sign: Round signs with a red border, diagonal red line, and white background that indicate actions or behaviours that are not permitted, such as "No Smoking" or "No Unauthorised Access".

- Mandatory Sign: Circular blue signs with white pictograms that communicate actions that must be taken, typically related to wearing personal protective equipment like safety helmets, eye protection, or high-visibility clothing.

- Warning Sign: Triangular yellow signs with black borders and symbols that alert people to specific hazards including electricity, slippery surfaces, overhead loads, or toxic substances.

- Photoluminescent: Signs manufactured with materials that absorb ambient light and glow in darkness, ensuring critical emergency and exit signage remains visible during power failures without requiring electrical connection or batteries.

Who Uses Safety Signs?

- Construction Site Managers: Marking hazards, controlling site access, and ensuring PPE compliance across active building projects

- Facilities Managers: Maintaining workplace safety standards in commercial buildings, warehouses, and industrial premises

- Electrical Contractors: Identifying 240v electrical hazards, isolations, and restricted access to electrical installations

- Factory and Manufacturing Supervisors: Highlighting machinery risks, emergency procedures, and mandatory safety protocols in production environments

- Health and Safety Officers: Implementing comprehensive signage strategies that meet HSE requirements and protect employees

- Warehouse Operators: Marking forklift routes, loading bays, height restrictions, and storage area hazards

- Property Landlords: Ensuring rental properties and commercial units meet statutory fire safety and hazard warning requirements

- Schools and Institutions: Providing clear safety guidance in workshops, laboratories, and maintenance areas

- Maintenance Engineers: Placing temporary warning signs during repairs, cleaning, or equipment servicing

How to Choose the Right Safety Signs

Identify the Hazard Type: Determine whether you need warning signs (triangular yellow) for hazards, prohibition signs (circular red) for forbidden actions, mandatory signs (circular blue) for required behaviours, or emergency information signs (rectangular green). Each category uses specific colours and shapes defined by regulations to ensure instant recognition.

Select Appropriate Material: Choose rigid plastic or aluminium signs for permanent installation in fixed locations, self-adhesive vinyl for smooth surfaces where drilling isn't possible, and photoluminescent materials for emergency exit signs that must remain visible during power failures. Consider weather-resistant materials for outdoor applications exposed to rain, UV light, and temperature variations.

Determine Size and Visibility: Sign dimensions should be proportional to viewing distance—larger signs for warehouse spaces viewed from distance, smaller formats for close-proximity warnings on machinery or equipment. Consider ambient lighting conditions and potential obstructions that might reduce visibility. The HSE provides guidance on minimum viewing distances for different sign sizes.

Verify Regulatory Compliance: Ensure signs meet BS EN ISO 7010 standards, particularly when replacing older signage using outdated symbols. Check that mandatory signs correctly represent the specific PPE requirements for your workplace, and that emergency signage includes appropriate pictograms and directional arrows where needed.

Consider Mounting Options: Assess whether you need wall-mounted signs, suspended ceiling signs, floor-standing barriers with integrated signage, or magnetic signs for temporary applications on metal surfaces. Some situations require signs visible from multiple angles, necessitating double-sided or projecting formats.

Popular Accessories

- Sign Fixing Kits: Adhesive pads, drill-and-screw fixings, cable ties, and magnetic mounts for secure installation

- Sign Cleaning Products: Suitable cleaning solutions that maintain sign visibility without damaging printed surfaces or photoluminescent coatings

- Barrier Tape and Chains: Temporary hazard marking for cordoning off dangerous areas during maintenance or emergencies

- Floor Marking Tape: Durable adhesive tape for creating walkways, hazard zones, and social distancing markers

- Document Holders: Weatherproof display pockets for site-specific risk assessments, method statements, and emergency procedures

- Lockout/Tagout Equipment: Devices that secure machinery during maintenance alongside "Do Not Operate" signage

- First Aid Cabinets: Wall-mounted storage with integrated first aid symbol signage for easy identification

Safety Information

Safety signs themselves do not eliminate hazards—they form part of a comprehensive control strategy alongside engineering controls, safe systems of work, and proper training. Never rely solely on signage when more effective control measures are available. The Health and Safety (Safety Signs and Signals) Regulations 1996 require employers to provide and maintain safety signs where risks cannot be avoided or controlled by other means, but signs must supplement rather than replace proper risk management.

Regularly inspect all safety signage to ensure it remains legible, correctly positioned, and relevant to current workplace conditions. Faded, damaged, or obscured signs fail to communicate critical safety information and may indicate non-compliance during HSE inspections. When installing signs near electrical installations or 240v equipment, ensure mounting methods don't create additional hazards or interfere with equipment operation. Always switch off power supplies before drilling near electrical circuits or cable routes.

Provide adequate information and training to employees and contractors so they understand what each sign means and what actions they must take. Simply displaying signs without ensuring comprehension, particularly in workplaces with non-English speakers or temporary workers, does not fulfil your duty of care under health and safety legislation.

Frequently Asked Questions

What's the difference between warning signs and mandatory signs?

Warning signs are triangular with yellow backgrounds and black borders, alerting people to specific hazards like electricity, slippery floors, or overhead loads. Mandatory signs are circular with blue backgrounds and white pictograms, indicating actions that must be taken, typically requiring specific PPE such as safety helmets, hearing protection, or high-visibility clothing. Warning signs say "be aware of this hazard," while mandatory signs say "you must do this."

Do safety signs need to comply with specific UK standards?

Yes, workplace safety signs must comply with the Health and Safety (Safety Signs and Signals) Regulations 1996, which implement European directive requirements in UK law. Signs should conform to BS EN ISO 7010, which standardises colours, shapes, and pictograms. Older sign formats using different symbols remain legally acceptable if already installed, but when purchasing new signage or replacing damaged signs, choose current BS EN ISO 7010 compliant versions for consistency and universal recognition.

Where should safety signs be positioned for maximum effectiveness?

Position signs at eye level where possible, ensuring they're visible from the direction people approach the hazard. Place warning signs before people reach the dangerous area, giving them time to respond appropriately. Emergency exit signs should be visible from any position within the space they serve, with directional arrows guiding people along escape routes. Ensure signs aren't obscured by equipment, stored materials, or opened doors, and provide adequate lighting or photoluminescent materials for visibility in all conditions.

How often should safety signs be replaced or updated?

Replace safety signs whenever they become faded, damaged, illegible, or no longer relevant to workplace hazards. UV exposure, harsh weather, and cleaning chemicals gradually degrade sign materials, particularly outdoors. Conduct regular inspections—monthly in high-traffic or harsh environments, quarterly in protected indoor locations. Update signage immediately when workplace layouts change, new hazards are introduced, or PPE requirements are modified. Regulatory changes may also necessitate updates to ensure continued compliance with current HSE guidance.

Can I create custom safety signs for specific workplace hazards?

Yes, custom signs addressing site-specific hazards not covered by standard signage are often necessary for comprehensive workplace safety. However, custom signs should still follow the colour, shape, and design principles established in BS EN ISO 7010 to maintain consistency and instant recognition. For example, use the triangular yellow format with black border for warnings, and include clear pictograms or concise text. Avoid creating custom signs for hazards already covered by standard signage, as this may cause confusion and reduce the effectiveness of your overall safety communication strategy.