Sanding Discs

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

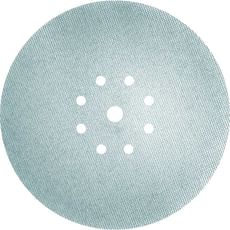

Bosch EXPERT C470 Hook and Loop Sandpaper for Random Orbital Sanders 150mm

in stock

Black and Decker Piranha Hi Tech Quick Fit Mesh ROS Sanding Sheets 115mm

in stock

Bosch EXPERT C470 Hook and Loop Sandpaper for Random Orbital Sanders 125mm

in stock

Black and Decker Piranha Hi Tech Quick Fit Mesh ROS Sanding Sheets 150mm

in stock

Loading...

Loading...

End of content

Error - No more pages to load

About Sanding Discs

Sanding discs are essential abrasive consumables designed to fit a wide range of power sanders, including random orbital sanders, angle grinders, and rotary tools. Available in various diameters from 115mm to 225mm, these circular abrasives feature different backing types – from hook and loop (Velcro-style) attachments to fibre discs for angle grinders – making them suitable for everything from fine finishing work to aggressive material removal. The variety of grit grades available means tradespeople and DIY enthusiasts can tackle diverse applications, from initial surface preparation through to final polishing stages.

Tooled-Up.com stocks sanding discs from leading manufacturers including Bosch Professional, DeWalt, and Black and Decker, with specialised options for different materials. Wood sanding discs typically feature aluminium oxide or ceramic abrasives for efficient stock removal and smooth finishing, whilst metal sanding discs use zirconia or ceramic grains that withstand the heat generated when working with ferrous and non-ferrous metals. Stone and masonry discs are engineered with silicon carbide for cutting through concrete, brick, and natural stone. Modern mesh sanding discs offer superior dust extraction compared to traditional paper-backed alternatives, extending disc life whilst maintaining a cleaner working environment.

The backing material significantly affects disc performance and longevity. Paper-backed discs suit lighter applications and fine finishing work, whilst cloth or fibre-backed options provide the durability required for heavy-duty grinding and aggressive sanding. Multi-hole patterns ensure compatibility with various sander extraction systems, essential for meeting HSE dust control requirements on professional worksites. Premium ranges like the Bosch Expert C470 series incorporate anti-clog technology that prevents material buildup, maintaining consistent cutting performance throughout the disc's lifespan.

Jargon Buster

- Grit Rating: A numerical value indicating abrasive particle size – lower numbers (40-80 grit) mean coarser abrasives for heavy material removal, whilst higher numbers (180-400 grit) denote finer particles for smooth finishing and polishing work.

- Hook and Loop: A Velcro-style attachment system allowing quick disc changes without tools, commonly found on random orbital sanders and providing secure fixing during operation whilst enabling easy removal when the disc is worn.

- Multi-Hole Pattern: Perforation arrangement across the disc surface that aligns with sander extraction ports, facilitating dust removal to prevent clogging, improve finish quality, and extend abrasive life whilst reducing airborne particle exposure.

- Zirconia Alumina: A tough synthetic abrasive grain that fractures during use to expose fresh cutting edges, particularly effective on metal applications where heat generation is high and conventional aluminium oxide would dull quickly.

- Anti-Clog Coating: A stearate or zinc stearate treatment applied to prevent material buildup on the abrasive surface, especially beneficial when sanding resinous softwoods, painted surfaces, or materials that generate sticky residue.

- Fibre Backing: A vulcanised fibre disc construction designed specifically for angle grinder use, providing the rigidity and durability required for aggressive grinding whilst withstanding the lateral forces generated during operation.

Who Uses Sanding Discs?

- Carpenters and Joiners: For smoothing timber components, removing mill marks, and preparing surfaces before finishing with varnish, lacquer, or paint

- Cabinet Makers and Furniture Makers: Fine finishing work requiring progressive grit sequences to achieve showroom-quality surfaces on hardwoods and veneers

- Decorators and Painters: Surface preparation including paint removal, filling compound smoothing, and keying existing finishes to ensure proper adhesion

- Metal Fabricators and Welders: Removing weld spatter, grinding weld seams flush, deburring cut edges, and achieving specific surface finishes on steel and aluminium

- Floor Fitters and Refinishers: Levelling timber floors, removing old finishes, and progressive sanding before applying oils, lacquers, or sealants

- Automotive Bodywork Specialists: Preparing panels for paint, flatting primer coats, and cutting back lacquer to achieve mirror finishes

- Construction and Renovation Professionals: General site work including drywall finishing, concrete smoothing, and removing surface imperfections from various building materials

- DIY Enthusiasts and Home Improvers: Furniture restoration, preparation work before decorating, and general workshop projects requiring quality surface finishing

How to Choose the Right Sanding Discs

Diameter and Fitting Type: Match disc diameter precisely to your power tool – common sizes include 115mm, 125mm, 150mm, and 225mm. Random orbital sanders typically use hook and loop fixing, whilst angle grinders require fibre-backed discs with centre arbor holes. The extensive selection at Tooled-Up includes quick-fit mesh formats compatible with specific sander models from Black and Decker, Bosch, and other major manufacturers.

Material Compatibility: Select discs engineered for your workpiece material. Wood sanding discs feature aluminium oxide or ceramic grains optimised for timber species, whilst metal applications demand zirconia or ceramic abrasives that resist heat buildup. Stone and masonry work requires silicon carbide discs that won't shatter when encountering aggregate. Using material-specific discs dramatically improves efficiency and extends abrasive life.

Grit Progression: Plan your sanding sequence strategically. Begin with coarser grits (40-80) for substantial material removal or stripping old finishes, progress through medium grits (100-120) for general smoothing, and finish with fine grits (180-240+) for final surface preparation. Skipping grit stages leaves visible scratches that become apparent after applying finishes.

Backing Material and Durability: Paper-backed discs suit lighter applications and fine finishing, offering good conformability around contours. Cloth-backed options provide greater tear resistance for edge work and moderately aggressive sanding. Fibre discs deliver maximum durability for heavy grinding on angle grinders. Mesh alternatives combine durability with superior dust extraction, reducing clogging and maintaining consistent cutting action.

Dust Extraction Compatibility: Prioritise multi-hole patterns that align with your sander's extraction ports, particularly important for COSHH compliance on professional sites. Effective dust removal prevents disc clogging, improves surface finish quality, extends abrasive life, and crucially reduces harmful airborne particle exposure during extended sanding operations.

Professional vs DIY Grades: Professional-grade discs from ranges like Bosch Expert C470 incorporate anti-clog coatings, premium grain structures, and reinforced backing materials that justify higher initial costs through extended lifespan and consistent performance. DIY-grade options suit occasional use where absolute longevity matters less than upfront affordability.

Popular Accessories

- Random Orbital Sanders: 240v corded and cordless models from Bosch, Makita, and DeWalt designed specifically for hook and loop sanding disc attachment

- Angle Grinders: 115mm and 125mm grinders for using fibre-backed sanding and grinding discs on metal fabrication and heavy material removal

- Backing Pads: Replacement hook and loop pads for random orbital sanders when Velcro surfaces become worn or contaminated

- Dust Extraction Systems: Workshop vacuums and on-tool extractors essential for maintaining clean working conditions and HSE compliance

- Sanding Blocks and Hand Sanders: Manual alternatives for detail work, edges, and areas inaccessible to power tools

- Respirators and Face Masks: FFP2 and FFP3 respiratory protection for sanding operations generating fine dust particles

- Safety Glasses and Goggles: Essential eye protection against flying debris and dust during sanding operations

- Work Gloves: Anti-vibration and grip-enhanced gloves reducing hand fatigue during extended sanding sessions

- Tool Storage Solutions: Organisers and cases from Stanley, DeWalt TSTAK, and Makita MakPac systems for protecting abrasive consumables

Safety Information

Respiratory Protection: Sanding generates fine dust particles that pose serious respiratory hazards, particularly when working with hardwoods, MDF, and materials containing preservatives or old paint potentially containing lead. Always use appropriate respiratory protection rated to HSE standards – minimum FFP2 for general sanding, FFP3 for hazardous materials. Connect power tools to suitable dust extraction systems wherever possible to minimise airborne particle generation at source, meeting COSHH workplace exposure limits.

Eye and Face Protection: Wear impact-rated safety glasses or goggles throughout sanding operations to prevent eye injury from flying debris and dust particles. Face shields provide additional protection during aggressive grinding work on angle grinders where larger particles are generated.

Disc Condition and Speed Ratings: Inspect sanding discs before fitting – never use damaged, torn, or contaminated abrasives. Check that disc speed ratings meet or exceed your tool's maximum RPM; exceeding rated speeds can cause catastrophic disc failure. Ensure hook and loop discs are centred correctly and firmly attached before starting tools, and allow angle grinder-mounted discs to reach full speed before contacting workpieces.

Secure Workpiece Clamping: Always secure workpieces properly before sanding – never attempt to sand items held solely by hand. Unexpected tool movement or workpiece slippage causes loss of control, potentially resulting in injury. Use appropriate clamping, vices, or workbenches to maintain stability throughout operations.

Ventilation and Fire Hazards: Work in well-ventilated areas, particularly when sanding materials that generate toxic dust. Be aware that fine wood dust presents explosion risks in confined spaces with ignition sources. Metal grinding produces sparks capable of igniting flammable materials – clear work areas of combustibles and have appropriate fire extinguishers accessible. Never sand magnesium alloys with standard abrasives as friction can ignite the material.

Frequently Asked Questions

What's the difference between sanding discs for wood and metal?

Wood sanding discs typically use aluminium oxide or ceramic grains with open coat patterns that resist clogging from wood fibres and resin. Metal discs feature zirconia alumina or ceramic grains engineered to withstand higher temperatures generated by metal work, with tougher backing materials. Using wood discs on metal causes rapid dulling, whilst metal discs on wood may be unnecessarily aggressive and expensive for the application.

How do I know when to replace a sanding disc?

Replace discs when abrasive grains are visibly worn smooth, when clogging cannot be cleared by cleaning, when backing material shows tears or delamination, or when sanding efficiency noticeably decreases requiring excessive pressure. Continuing with worn discs reduces productivity, generates excessive heat, and risks poor surface finish quality. Professional users typically replace discs proactively rather than working them to complete failure.

Can I use any diameter disc on my sander?

No – always use the exact disc diameter specified for your sander model. Oversized discs create dangerous imbalance and may contact the tool housing or your workpiece uncontrollably. Undersized discs won't engage properly with backing pads and extraction holes won't align correctly. Common diameters include 115mm, 125mm, and 150mm for random orbital sanders, with 225mm for specialised drywall sanders. Check your tool's manual for correct specifications.

What grit should I start with for paint removal?

For stripping paint from wood, begin with 60-80 grit to remove the bulk of coating efficiently without excessive aggression that might damage underlying timber. Progress to 120 grit to smooth scratches left by coarser abrasives, then 180-240 grit for final surface preparation before applying new finishes. On metal surfaces, start with 80 grit, though heavily built-up paint may require initial scraping or chemical strippers before sanding.

Why do mesh sanding discs cost more than paper versions?

Mesh discs manufactured from woven abrasive material offer significantly longer lifespan than paper equivalents because hundreds of small perforations provide superior dust extraction, dramatically reducing clogging. This maintains consistent cutting performance throughout the disc's life and allows continued use long after paper discs would be exhausted. Professional users find the higher initial cost offset by reduced disc changes, improved productivity, and cleaner working conditions. Black and Decker Piranha mesh discs available from Tooled-Up exemplify this technology with silicon carbide grains on durable cloth backing.