VDE Sockets & Ratchets

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About VDE Sockets & Ratchets

VDE sockets and ratchets are specialist hand tools designed for electricians and other tradespeople who work on or near live electrical systems. Unlike standard socket sets, VDE-certified tools feature heavy-duty insulation that protects users from electric shock when working with voltages up to 1000V AC or 1500V DC. Each tool is individually tested to 10,000V and manufactured to strict EN 60900 and IEC 60900 standards, making them essential safety equipment for any electrical work involving 240v mains power or higher voltage installations.

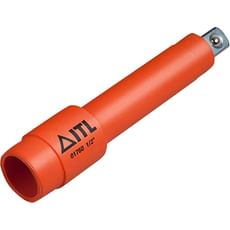

The VDE socket and ratchet range at Tooled-Up.com includes fully insulated hexagon sockets in 1/4", 3/8" and 1/2" drive sizes, extension bars, and ratchet handles from trusted brands including Draper, Wera, Wiha, Sealey and ITL. These tools are manufactured from chrome vanadium steel that's hardened, tempered and chrome plated for durability, then coated with a distinctive two-tone insulation layer. The bright colour scheme—typically red and yellow or orange—serves a practical purpose, making any damage to the insulation immediately visible so compromised tools can be taken out of service before they pose a safety risk.

Whether you're an electrical contractor working on consumer units, an industrial electrician maintaining factory equipment, or a renewable energy installer working with solar inverters, VDE-certified sockets and ratchets provide the protection required by law when working on live circuits. Tooled-Up stocks individual VDE sockets, extension bars and ratchets as well as comprehensive socket sets that provide excellent value for tradespeople kitting out their toolkit to meet health and safety requirements.

Jargon Buster

- VDE Certification: A safety standard administered by the German VDE Testing and Certification Institute, certifying that insulated tools meet EN 60900 requirements for safe live working up to 1000V AC. Each VDE tool is individually tested and marked with a certification number.

- Live Working: Performing maintenance, testing or installation work on electrical equipment whilst it remains energised. This practice requires specialist VDE-rated tools and appropriate training as mandated by the Electricity at Work Regulations 1989.

- Two-Layer Insulation: VDE sockets feature an inner insulating layer (typically orange or red) beneath an outer yellow layer. If the outer layer becomes damaged, the contrasting colour underneath provides an immediate visual warning that the tool must be withdrawn from service.

- EN 60900 Standard: The European safety standard specifying requirements for insulated tools for live working. Tools must withstand a test voltage of 10,000V AC to be certified for use at 1000V AC or 1500V DC working voltage.

- Drive Size: The square drive fitting (1/4", 3/8" or 1/2") that connects sockets to ratchets and extension bars. Larger drive sizes provide greater torque capacity for bigger fasteners, whilst smaller drives suit confined spaces and lighter work.

- Chrome Vanadium Steel: A high-strength alloy used in quality socket manufacture, offering excellent hardness, durability and resistance to wear whilst maintaining enough flexibility to prevent cracking under stress.

Who Uses VDE Sockets & Ratchets?

- Electricians and Electrical Contractors: Domestic, commercial and industrial sparkies working on consumer units, distribution boards, lighting circuits and power installations

- Maintenance Engineers: Factory and facilities maintenance personnel servicing machinery, motors, control panels and electrical equipment whilst minimising production downtime

- Renewable Energy Installers: Solar PV installers and wind turbine technicians working with DC systems and high-voltage inverters

- Control Panel Builders: Specialists constructing and wiring industrial control systems, switchgear and automation equipment

- Rail and Transport Electricians: Engineers maintaining signalling systems, overhead lines and rolling stock electrical systems

- Telecommunications Engineers: Technicians working on exchange equipment, street cabinets and telecommunications infrastructure

- Automotive Electricians: Specialists working on hybrid and electric vehicle high-voltage battery systems and charging equipment

- Apprentice Electricians: Trainees building their first professional toolkit to meet college and workplace safety requirements

How to Choose the Right VDE Sockets & Ratchets

Drive Size Selection: Consider what size fasteners you typically encounter. A 1/4" drive VDE set covers smaller fixings (4mm-13mm) commonly found in domestic consumer units and control panels. The 3/8" drive offers a versatile middle ground, whilst 1/2" drive sockets handle larger industrial applications and cable gland lockrings. Many electricians invest in both 1/4" and 3/8" drive sets for maximum flexibility.

Individual Tools vs. Complete Sets: If you only occasionally need VDE tools, purchasing individual sockets and a ratchet may prove economical. However, comprehensive VDE socket sets from brands like Draper, Wera and Wiha typically offer better value and come supplied in protective storage cases. The Draper XP1000 VDE socket sets available from Tooled-Up.com include everything needed for most electrical work, from sockets and ratchets to extension bars.

Certification and Compliance: Always verify that tools carry genuine VDE or equivalent EN 60900 certification with individual test certificates. Each socket and tool should be clearly marked with the certification symbol, working voltage (1000V), and unique certification number. Avoid uncertified "electrician's tools" that lack proper insulation testing—your safety and legal compliance depend on genuine VDE certification.

Insulation Condition: Inspect the two-layer insulation system carefully. Quality VDE sockets feature a contrasting inner layer that becomes visible if the outer insulation is damaged. This safety feature is critical—once the outer layer is breached, the tool must be replaced immediately. Establish a regular inspection routine and withdrawal policy for your VDE toolkit.

Brand Quality and Warranty: Professional-grade VDE tools from established manufacturers like Wera, Wiha and Draper offer superior build quality, better ergonomics and comprehensive warranties. These tools represent a safety investment that protects both you and your business, so prioritise quality over bargain basement alternatives.

Popular Accessories

- VDE Screwdrivers and Bit Sets: Insulated screwdrivers, nut drivers and bit holders to complement your socket set for complete electrical toolkit coverage

- VDE Pliers and Cutters: Insulated side cutters, combination pliers and long-nose pliers from Knipex, Wiha and Wera for safe wire manipulation

- Voltage Testers and Multimeters: Proving units and two-pole voltage detectors to verify isolation before commencing work—essential safety equipment alongside VDE tools

- Insulated Adjustable Spanners: VDE-rated adjustable wrenches for cable glands, lockrings and larger fixings beyond socket range

- Tool Storage Cases: Dedicated VDE tool cases and pouches to protect insulation from damage and keep certified tools separate from standard equipment

- Insulated Torque Wrenches: VDE torque wrenches for applications requiring precise tightening specifications whilst maintaining electrical safety

- Cable Strippers and Knives: Insulated cable preparation tools for safely preparing conductors during installation work

Safety Information

Regular Inspection is Mandatory: Before each use, carefully inspect all VDE tools for damage to the insulation. Any cracks, cuts, abrasion or exposure of the inner insulation layer means the tool must be immediately withdrawn from service. The Electricity at Work Regulations 1989 require that electrical tools are maintained in safe condition—damaged VDE tools represent a serious breach of safety legislation.

Training and Competence: VDE tools do not replace proper training. Only competent persons who understand electrical hazards and safe isolation procedures should attempt live working. The HSE recommends avoiding live working wherever possible—VDE tools are for situations where de-energisation is genuinely impractical, not a shortcut around proper isolation.

Cleaning and Storage: Clean VDE tools with a soft cloth and mild detergent—never use solvents or abrasive cleaners that could degrade the insulation. Store tools in their protective cases away from sharp objects, extreme temperatures and direct sunlight, all of which can compromise insulation integrity over time.

Voltage Limits: VDE-certified tools are rated for 1000V AC or 1500V DC maximum working voltage. Never use them on higher voltage systems. Always verify the system is de-energised using a proving unit before commencing work, even when using VDE tools as an additional safety precaution.

Frequently Asked Questions

Q: Are VDE tools a legal requirement for electricians?

A: Whilst the Electricity at Work Regulations 1989 don't explicitly mandate VDE tools, they require appropriate equipment for safe working. When working on or near live conductors at 240v mains voltage or higher, VDE-certified insulated tools are considered essential safety equipment. Using non-insulated tools on live circuits would typically constitute a breach of health and safety law.

Q: What's the difference between VDE and standard insulated tools?

A: Genuine VDE tools are individually tested to 10,000V and certified to EN 60900, with each tool bearing a unique certification mark and number. Standard "insulated" tools often feature basic handle coating but lack the rigorous testing, two-layer insulation system, and certification required for safe live working. Only VDE-certified tools provide reliable protection.

Q: How often should VDE tools be replaced?

A: There's no fixed replacement schedule—VDE tools should be replaced immediately if insulation damage occurs, regardless of age. With proper care and regular inspection, quality VDE sockets and ratchets can provide many years of safe service. However, establishing a formal inspection and withdrawal policy is essential for compliance and safety.

Q: Can I use VDE sockets with standard non-insulated ratchets?

A: No—using VDE sockets with non-insulated ratchets or extension bars defeats the entire purpose of electrical safety. The complete drive train from socket through extension bars to ratchet handle must be VDE-certified to provide continuous insulated protection. Always use matched VDE components as a complete system.

Q: Why are VDE tools more expensive than standard sockets?

A: VDE tools undergo individual high-voltage testing (not batch testing), feature specialised two-layer insulation systems, and carry legal liability certification. The manufacturing process is more complex and quality control more rigorous than standard tools. This investment protects your life and livelihood—VDE certification is worth the premium when working with electrical hazards.