Bosch Professional Sander Base Plates

Loading...

Loading...

End of content

Error - No more pages to load

Bosch Professional Sander Base Plates at Tooled-Up.com

When it comes to maintaining and optimising professional sanding equipment, Bosch Professional sander base plates represent the gold standard for tradespeople and serious DIY enthusiasts across the UK. These precision-engineered components are designed to extend the life of your sanding tools whilst delivering consistent, professional-grade results across a wide range of applications. Tooled-Up.com stocks an extensive selection of genuine Bosch Professional sander base plates, ensuring compatibility with the full range of Bosch orbital, random orbital, and detail sanders used throughout the construction, woodworking, and automotive industries.

Bosch Professional sander base plates are manufactured to exacting German engineering standards, providing the perfect foundation for efficient material removal and superior surface finishing. Whether you're replacing a worn base plate on your trusted GEX series random orbital sander or upgrading your GSS orbital sander for specific applications, these genuine Bosch components ensure your equipment performs exactly as intended. Each base plate features precision-machined surfaces, optimised hook-and-loop fastening systems, and carefully balanced weight distribution to minimise vibration and operator fatigue during extended use.

The range available from Tooled-Up encompasses base plates for various sander models and sanding pad sizes, from compact detail sanders through to larger 150mm random orbital configurations. Bosch Professional's commitment to backwards compatibility means that many base plates fit multiple sander generations, providing excellent value and longevity for professional tool investments whilst maintaining the brand's renowned build quality and performance standards.

Why Choose Bosch Professional Sander Base Plates?

Bosch Professional has built an unrivalled reputation within the power tool industry over more than a century of innovation, and their sander base plates exemplify this commitment to quality and durability. Unlike generic aftermarket alternatives, genuine Bosch Professional base plates are manufactured using premium-grade aluminium alloys and engineering polymers that resist warping, chemical damage, and the rigours of daily professional use. The precision fit guarantees optimal balance and reduces harmful vibrations that can lead to both poor finishing results and long-term health issues for operators.

The engineering excellence behind Bosch Professional sander base plates extends to their hook-and-loop attachment systems, which maintain superior holding power even after thousands of abrasive disc changes. This reliability translates directly to reduced downtime on site and lower consumable costs, as abrasive discs remain securely attached throughout their useful life without premature detachment or uneven wear patterns. Furthermore, genuine Bosch components maintain your tool's warranty coverage and ensure compliance with UK health and safety regulations regarding power tool maintenance and performance standards.

Bosch Professional's extensive research and development capabilities mean their base plates incorporate the latest innovations in dust extraction efficiency, with carefully designed perforation patterns that maximise airflow whilst maintaining structural integrity. This attention to detail results in cleaner working environments, reduced health risks from airborne particulates, and longer abrasive life thanks to improved debris removal from the working surface.

Who Uses Bosch Professional Sander Base Plates?

Bosch Professional sander base plates are the component of choice for demanding trades and industries where consistent quality and reliability cannot be compromised:

- Joiners and Cabinet Makers who require flawless surface preparation for fine furniture and bespoke joinery projects

- Automotive Body Repair Technicians performing precision refinishing work on vehicle panels and composite materials

- Shopfitters and Contractors working on commercial installations requiring high-volume sanding across various substrates

- Floor Fitting Specialists preparing and finishing hardwood, laminate, and engineered flooring systems

- Painting and Decorating Professionals undertaking preparation work across residential and commercial properties

- Boat Builders and Marine Engineers working with GRP, timber, and composite materials in demanding environments

- Workshop Technicians and Maintenance Engineers maintaining equipment and fabrications across manufacturing facilities

- Restoration Specialists working on heritage properties and antique furniture requiring careful, controlled material removal

Key Features of Bosch Professional Sander Base Plates

Bosch Professional sander base plates incorporate numerous technical features that distinguish them from generic alternatives. The precision-balanced construction minimises vibration transfer to the operator, reducing fatigue during extended sanding sessions whilst improving finish quality through consistent pad contact with the work surface. High-grade aluminium alloy construction provides excellent heat dissipation properties, preventing thermal distortion during intensive use that could compromise sanding accuracy.

The hook-and-loop fastening system utilises industrial-grade materials tested to withstand tens of thousands of attachment cycles without performance degradation. Strategic perforation patterns are computer-optimised for each base plate size and sander model, ensuring maximum dust extraction efficiency when connected to suitable 240V vacuum systems or Bosch Professional dust extractors. This design consideration significantly improves visibility of the working area and reduces the health risks associated with prolonged exposure to sanding dust.

Bosch Professional base plates feature precision-machined mounting interfaces that ensure perfect alignment with the sander's drive mechanism, eliminating wobble and ensuring uniform orbital or random orbital motion. Protective edge treatments resist impact damage from accidental contact with fixtures and fittings, extending component life in real-world working conditions. Many models incorporate quick-change mechanisms that simplify pad replacement during multi-stage finishing processes, saving valuable time on site.

Popular Bosch Professional Sander Base Plates

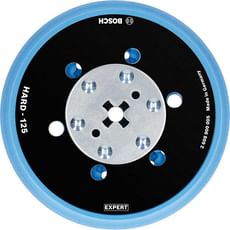

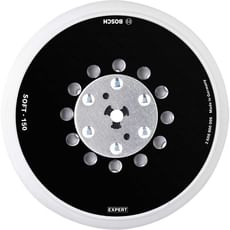

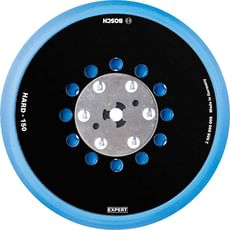

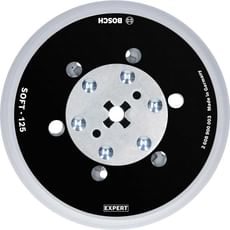

The Bosch Professional sander base plate range at Tooled-Up encompasses components for the brand's most popular professional sanding platforms. Base plates for the GEX series random orbital sanders are particularly sought-after, available in 125mm and 150mm configurations to suit different application requirements. These precision components ensure the characteristic Bosch random orbital action continues to deliver swirl-free finishes across timber, metal, plastics, and composite materials.

For detail and finish sanding applications, base plates compatible with Bosch Professional GSS orbital sanders provide the stable platform required for edge work and confined spaces. Multi-hole perforation patterns on these models accommodate various abrasive disc configurations, from 8-hole to 14-hole arrangements, ensuring compatibility with both Bosch and third-party abrasive systems. Replacement base plates for palm sanders and compact orbital models are also available, extending the working life of these essential finishing tools.

Specialist base plates designed for specific applications include soft-backed variants for contoured surfaces, rigid plates for aggressive stock removal, and extended reach plates for accessing recessed areas. Tooled-Up stocks base plates suitable for both corded 240V models and cordless battery-powered sanders across the Bosch Professional 18V system, ensuring comprehensive coverage of the brand's sanding tool ecosystem.

Safety and Compliance

Using genuine Bosch Professional sander base plates is essential for maintaining compliance with UK health and safety regulations, particularly the Control of Substances Hazardous to Health (COSHH) Regulations and the Provision and Use of Work Equipment Regulations (PUWER). Correctly maintained equipment with properly fitted base plates ensures optimal dust extraction performance, reducing operator exposure to respirable crystalline silica and wood dust particles that pose serious long-term health risks.

All Bosch Professional sander base plates meet relevant BS EN standards for power tool accessories and are designed to maintain the safety certifications of the host sander when correctly installed. Regular inspection of base plates for wear, damage, or deterioration of the hook-and-loop surface is essential for safe operation. Worn base plates should be replaced promptly to prevent abrasive disc detachment during operation, which presents a significant hazard to operators and bystanders.

When installing replacement base plates, always ensure the sander is disconnected from 240V mains power or that battery packs are removed. Follow the manufacturer's installation procedures precisely, using only specified fasteners torqued to the correct specifications. Never attempt to modify or repair damaged base plates, as this compromises both safety and performance whilst potentially voiding tool warranties and insurance coverage.

Frequently Asked Questions

How often should I replace my Bosch Professional sander base plate?

Base plate replacement intervals depend on usage intensity and working conditions. Professional tradespeople working daily should inspect base plates monthly for wear, warping, or hook-and-loop degradation. Replace immediately if abrasive discs no longer attach securely, if visible damage is present, or if the base plate shows signs of warping that affects sanding performance. In typical professional use, expect 12-24 months of service life, though demanding applications may require more frequent replacement.

Are Bosch Professional sander base plates compatible with other brands of abrasive discs?

Yes, genuine Bosch Professional base plates feature standard hook-and-loop attachment systems compatible with most quality abrasive discs that match the appropriate hole pattern and diameter. However, Bosch Professional abrasives are specifically designed to work optimally with Bosch base plates, ensuring perfect alignment of dust extraction holes and maximising the performance of both components.

Can I use aftermarket base plates instead of genuine Bosch Professional components?

While aftermarket alternatives may appear similar and cost less initially, they rarely match the precision engineering, material quality, and durability of genuine Bosch Professional base plates. Non-genuine components may void your tool warranty, compromise dust extraction efficiency, increase vibration levels, and wear out significantly faster. For professional tradespeople whose livelihood depends on reliable equipment, genuine Bosch components represent far better value over the tool's lifetime.

What's the difference between rigid and soft base plates?

Rigid base plates provide a firm, flat surface ideal for aggressive stock removal and working on flat surfaces where consistent material removal is required. Soft or padded base plates incorporate a flexible backing that allows the sanding surface to conform to contoured or curved workpieces, making them essential for finishing shaped components, mouldings, and rounded edges without creating flat spots or uneven results.

How do I maintain my Bosch Professional sander base plate for optimal longevity?

Regular cleaning is essential – remove accumulated dust and debris from hook-and-loop surfaces using a wire brush or compressed air after each use. Avoid exposing base plates to excessive heat, solvents, or corrosive chemicals that could damage materials. Store sanders in protective cases when not in use to prevent impact damage. Periodically check mounting fasteners for tightness and inspect the hook-and-loop surface for wear or contamination that reduces abrasive disc retention. Replace worn hook-and-loop pads before they affect performance, as some Bosch models feature replaceable interface pads that extend base plate life.