Faithfull Jigsaw Blades

Loading...

Loading...

End of content

Error - No more pages to load

Faithfull Jigsaw Blades at Tooled-Up.com

Faithfull has established itself as a trusted name in the power tool accessories market, and their jigsaw blade range exemplifies the brand's commitment to delivering professional-grade performance at competitive prices. The Faithfull jigsaw blade collection available from Tooled-Up.com encompasses an extensive selection designed to tackle virtually every cutting application, from intricate curved cuts in hardwood to fast, aggressive cuts through metal and plastics. Each blade is manufactured to exacting standards, ensuring compatibility with all major jigsaw brands including Bosch, Makita, DeWalt, and others using the universal T-shank fitting system.

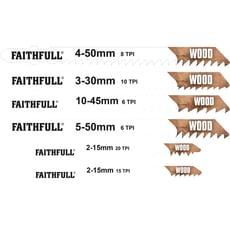

What distinguishes Faithfull jigsaw blades is their focus on delivering reliable, consistent performance across diverse materials and applications. The range includes specialised blades for wood, metal, laminate, ceramic, and multi-material cutting, each engineered with appropriate tooth configurations, blade thicknesses, and material compositions to optimise cutting efficiency. From fine-tooth blades for precision scrollwork to aggressive-cut blades for rapid material removal, Tooled-Up stocks Faithfull's comprehensive selection to meet the demands of both professional tradespeople and serious DIY enthusiasts.

Faithfull's jigsaw blades are manufactured using high-carbon steel (HCS), high-speed steel (HSS), and bi-metal constructions, with many featuring advanced coatings to reduce friction and extend blade life. The brand's attention to manufacturing quality ensures clean, splinter-free cuts with minimal vibration, whilst maintaining sharp cutting edges throughout extended use. Available in various lengths and tooth configurations, the Faithfull range provides solutions for everything from 6mm sheet materials to 100mm thick timber beams.

Why Choose Faithfull Jigsaw Blades?

Faithfull jigsaw blades represent exceptional value without compromising on performance or durability. The brand has built its reputation on delivering professional-quality accessories that compete directly with premium manufacturers whilst remaining accessible to budget-conscious tradespeople and DIY users. Each blade undergoes rigorous quality control to ensure dimensional accuracy, proper tooth set, and consistent material hardness throughout the cutting edge.

The universal T-shank design employed across the Faithfull jigsaw blade range guarantees secure blade retention and quick, tool-free blade changes on virtually all modern jigsaws. This standardisation eliminates compatibility concerns and allows users to build a versatile blade collection suitable for multiple machines. Faithfull's commitment to maintaining tight manufacturing tolerances means their blades run true with minimal wobble, resulting in straighter cuts and reduced material waste.

Another compelling reason to choose Faithfull is their extensive range of specialised blades for specific applications. Whether you're cutting kitchen worktops, installing flooring, fabricating metal components, or creating decorative scrollwork, there's a Faithfull blade engineered specifically for that task. This application-focused approach ensures optimal results rather than forcing users to compromise with general-purpose blades.

Who Uses Faithfull Jigsaw Blades?

- Carpenters and joiners requiring precise cuts in hardwoods, softwoods, and engineered timber products

- Kitchen fitters cutting worktops, plinths, and laminated panels with clean, chip-free edges

- Shopfitters working with diverse materials including MDF, plywood, and decorative laminates

- Electricians cutting access holes in floorboards, plasterboard, and plastic enclosures

- Plumbers making precise cuts in pipework, plastic panels, and access covers

- General builders tackling varied site work across multiple materials

- Metal fabricators cutting sheet metal, aluminium, and steel profiles

- Flooring installers precision-cutting laminate, engineered wood, and vinyl planks

- Maintenance engineers requiring versatile cutting solutions for repair work

- DIY enthusiasts seeking professional results for home improvement projects

Key Features of Faithfull Jigsaw Blades

Universal T-Shank Fitment: All Faithfull jigsaw blades feature the industry-standard T-shank design, ensuring compatibility with Bosch, Makita, DeWalt, Milwaukee, Festool, and virtually all modern jigsaw brands. This universal fitment eliminates compatibility concerns and allows for quick, tool-free blade changes.

Material-Specific Construction: Faithfull manufactures blades using appropriate materials for each application. High-carbon steel (HCS) blades excel in wood and soft materials, high-speed steel (HSS) variants tackle metal cutting, whilst bi-metal constructions combine flexibility with cutting edge hardness for demanding applications.

Precision-Ground Teeth: Each blade features accurately ground and set teeth that maintain their geometry throughout the blade's working life. This precision ensures consistent cutting performance, reduced splintering, and cleaner finished edges requiring minimal sanding or finishing.

Application-Optimised Geometry: Tooth pitch, gullet depth, and blade thickness are carefully matched to specific materials and cutting requirements. Fine-tooth blades deliver smooth, splinter-free cuts in laminates, whilst aggressive tooth patterns enable rapid stock removal in construction timber.

Advanced Coatings: Selected Faithfull blades feature friction-reducing coatings that decrease heat build-up, extend blade life, and improve cutting efficiency. These coatings are particularly beneficial when cutting abrasive materials or working with resinous timbers.

Popular Faithfull Jigsaw Blades

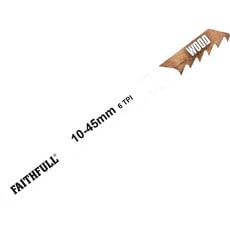

Wood Cutting Blades: The Tooled-Up range includes Faithfull's comprehensive selection of wood-cutting blades in various tooth configurations. Fast-cut blades with aggressive tooth patterns handle construction work and rough dimensioning, whilst fine-tooth variants deliver smooth, splinter-free cuts perfect for visible surfaces and furniture work. Extra-long blades accommodate thicker timbers up to 100mm.

Metal Cutting Blades: Faithfull's bi-metal and HSS blades provide efficient cutting through ferrous and non-ferrous metals, including steel sheet, aluminium profiles, and copper pipework. These specialised blades feature hardened cutting edges and flexible blade bodies that resist breakage during demanding metalwork applications.

Multi-Material Blades: Versatile carbide-grit and special-tooth blades handle materials that would quickly dull conventional blades, including fibreglass, ceramic tiles, cement board, and plastics. These all-purpose blades are ideal for maintenance work and general contracting where material types vary.

Laminate and Worktop Blades: Specifically designed for cutting kitchen worktops, flooring, and laminated panels, these blades feature reverse-tooth configurations or ultra-fine teeth that eliminate chipping on decorated surfaces, ensuring professional results on high-visibility installations.

Scrolling and Curved Cut Blades: Narrow-bodied blades enable tight radius cuts and intricate scrollwork in wood, plastic, and soft metals. These specialised blades are essential for decorative work, creating cut-outs, and following complex cutting patterns.

Safety and Compliance

Faithfull jigsaw blades are manufactured to meet relevant British and European safety standards for power tool accessories. Users should always ensure blades are appropriate for the material being cut and the jigsaw's specifications. Always disconnect the tool from the power supply before changing blades, and ensure the new blade is fully seated and locked in the blade holder before operation.

When using jigsaw blades, appropriate personal protective equipment is essential, including safety glasses to protect against flying debris and hearing protection when working for extended periods. Secure workpieces firmly before cutting, and maintain proper hand positioning away from the cutting line. Never force the jigsaw through material—allow the blade to cut at its own pace to prevent blade breakage and maintain control.

Regularly inspect blades for damage, wear, or bent teeth, and replace immediately if defects are found. Dull blades require excessive feed pressure and increase the risk of accidents. Store blades in their original packaging or a dedicated blade case to protect cutting edges and prevent injury when selecting blades. Always follow HSE guidance and manufacturer recommendations when using power tools and accessories in professional environments.

Frequently Asked Questions

Are Faithfull jigsaw blades compatible with all jigsaw brands?

Yes, Faithfull jigsaw blades feature the universal T-shank fitting system that works with all major jigsaw manufacturers including Bosch, Makita, DeWalt, Milwaukee, Festool, Black & Decker, and others. This standardised fitting has replaced older U-shank designs and ensures secure blade retention with quick, tool-free blade changes.

What's the difference between HCS, HSS, and bi-metal jigsaw blades?

HCS (high-carbon steel) blades are flexible and ideal for wood, plastic, and soft materials but wear quickly in abrasive applications. HSS (high-speed steel) blades are harder and designed specifically for metal cutting but are more brittle. Bi-metal blades combine an HSS cutting edge welded to a flexible HCS body, offering the best of both worlds—hard, wear-resistant teeth with a flexible, break-resistant blade body suitable for demanding applications.

How do I choose the right Faithfull jigsaw blade for my project?

Match the blade to your material: wood-cutting blades for timber, bi-metal or HSS for metals, and carbide-grit for abrasive materials. Consider the finish required—fine teeth (10-12 TPI or higher) produce smooth, splinter-free cuts for visible surfaces, whilst coarse teeth (6 TPI or fewer) cut faster but leave rougher edges. Blade length must accommodate your material thickness, typically requiring 25mm more length than the material depth.

Why do my jigsaw blades break or wear out quickly?

Premature blade failure typically results from forcing the tool through material, using an inappropriate blade for the application, or attempting to cut materials that are too thick for the blade length. Ensure you're using the correct blade type for your material, allow the jigsaw to cut at its own pace without excessive feed pressure, and check that your jigsaw's orbital action setting is appropriate—aggressive orbital action can damage fine-tooth blades.

Can Faithfull jigsaw blades cut curves and tight radii?

Yes, Faithfull manufactures narrow-bodied scrolling blades specifically designed for curved cuts and intricate work. These blades typically measure 4-6mm wide compared to standard 8-10mm blades, allowing much tighter turning radii. For the tightest curves, select the narrowest blade compatible with your material, and reduce cutting speed to maintain control and prevent blade deflection.