Sander Base Plates

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Sander Base Plates

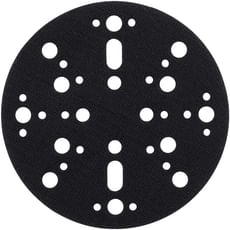

Sander base plates, also known as backing pads or sanding pads, are essential replacement components for random orbital sanders, delta sanders, and disc sanders. These circular or triangular plates form the interface between your power tool and the abrasive sanding disc, providing the crucial surface that holds sandpaper firmly in place during operation. Available in various diameters—typically 125mm and 150mm for orbital sanders—and different hardness grades, sander base plates directly influence the quality of finish you can achieve on different materials and surfaces.

The hardness of a backing pad is critical to sanding performance. Soft pads conform better to contoured surfaces and are ideal for final finishing work, providing a more forgiving action that reduces the risk of sanding through edges. Medium-density pads offer a balance between flexibility and flatness, making them suitable for general-purpose sanding tasks on both flat and slightly curved surfaces. Hard backing pads deliver maximum flatness and aggressive material removal, perfect for levelling work on large, flat surfaces such as tabletops or door panels. Tooled-Up.com stocks backing pads across all hardness grades from leading manufacturers including Bosch Professional and Festool, ensuring compatibility with the most popular professional sanders on the market.

Modern sander base plates feature multihole patterns that align with dust extraction ports, significantly improving dust collection efficiency during sanding operations. The quality of your backing pad affects not only the finish quality but also the lifespan of your abrasive discs. A worn or damaged base plate can cause uneven wear patterns on sandpaper, reduce dust extraction performance, and create unwanted vibration that affects both comfort and results.

Jargon Buster

- Backing Pad: The rubber or foam interface plate that attaches to your sander and holds the abrasive disc. Also called a sanding pad or base plate.

- Hardness Grade: The density of the backing pad material, categorised as soft, medium, or hard. This determines how much the pad flexes during use and affects the sanding characteristics.

- Multihole Pattern: The arrangement of holes in the backing pad that allows dust to be extracted through both the abrasive disc and the pad itself. Common patterns include 6-hole, 8-hole, and 9-hole configurations.

- Hook-and-Loop System: The Velcro-style fastening method used to attach sanding discs to the backing pad, allowing for quick disc changes without adhesives.

- Eccentric Action: The orbital motion of random orbital sanders that requires a specific type of backing pad designed to withstand the combined rotational and oscillating movement.

- Universal Backing Pad: A replacement pad designed to fit multiple sander models, offering flexibility when working with different tools or brands.

Who Uses Sander Base Plates?

- Joiners and Cabinet Makers: Replace worn pads to maintain fine finishing standards on furniture and fitted joinery

- Decorators and Painters: Use different hardness grades for preparing surfaces, from aggressive paint removal to final smoothing before coating

- Vehicle Body Repair Technicians: Require soft pads for contoured automotive panels and hard pads for flatting primer and filler

- Boat Builders and Restorers: Need flexible backing pads for working on curved hull surfaces and compound shapes

- Floor Fitters and Refinishers: Use hard backing pads for aggressive levelling work on wooden flooring

- General Building Contractors: Replace damaged pads as part of routine tool maintenance across various site applications

- Shopfitters and Retail Installation Teams: Maintain multiple sanders for different finish requirements on commercial projects

- DIY Enthusiasts: Upgrade or replace worn pads to improve results on home renovation and restoration projects

How to Choose the Right Sander Base Plates

Compatibility: The most critical factor is ensuring the backing pad fits your specific sander model. Check your tool's model number and match it to the manufacturer's recommended replacement pad. Brands like Bosch Professional and Festool manufacture pads designed specifically for their sander ranges, guaranteeing proper fitment and performance. The attachment method—typically a threaded connection or hook-and-loop Velcro system—must match your tool exactly.

Diameter: Sander base plates must match your tool's designated size. The most common sizes are 125mm (5 inches) and 150mm (6 inches) for random orbital sanders. Using an incorrectly sized pad will prevent proper operation and could damage your tool. Delta sanders require triangular pads specific to their model range.

Hardness Selection: Choose soft backing pads for final finishing work, contoured surfaces, and applications where you need to avoid sanding through edges or corners. Medium-density pads suit general-purpose work and offer the most versatility for everyday sanding tasks. Hard backing pads are available from Tooled-Up for aggressive stock removal, flattening work, and achieving perfectly level surfaces on large flat areas.

Hole Configuration: Match the hole pattern to your abrasive discs and your sander's dust extraction system. Multihole patterns provide superior dust extraction, keeping your work area cleaner and extending abrasive life. Eight-hole and nine-hole patterns are common, though some professional systems use proprietary patterns with more holes for maximum extraction efficiency.

Quality and Durability: Professional-grade backing pads from manufacturers like Bosch and Festool use higher-quality materials that resist compression, maintain their hardness characteristics over time, and feature more durable hook-and-loop surfaces. While budget options exist, professional tradespeople typically find that quality backing pads offer better value through extended lifespan and consistent performance.

Popular Accessories

- Sanding Discs: Hook-and-loop abrasive discs in various grits, from coarse 40-grit for heavy stock removal to ultra-fine 400-grit for finishing

- Interface Pads: Thin foam layers placed between the backing pad and abrasive disc to further soften the sanding action on contoured surfaces

- Dust Extraction Hoses: Connect your sander to a vacuum system for improved dust control and healthier working conditions

- Sanding Pad Cleaners: Rubber cleaning blocks that remove clogged dust and residue from hook-and-loop backing pads

- Replacement Velcro Surfaces: Self-adhesive hook-and-loop material to refurbish worn backing pads

- Anti-Vibration Gloves: Reduce hand fatigue and comply with HSE guidance on vibration exposure during extended sanding sessions

- Dust Extraction Adaptors: Connect sanders with proprietary dust ports to standard vacuum hose fittings

Safety Information

Always disconnect your sander from the 240v power supply before changing backing pads or performing any maintenance. Inspect backing pads regularly for damage, wear, or deterioration—a damaged pad can cause disc detachment or excessive vibration. Ensure replacement pads are properly tightened according to the manufacturer's specifications; an inadequately secured backing pad can work loose during operation, potentially causing injury.

Worn backing pads with degraded hook-and-loop surfaces may not securely hold abrasive discs, creating a projectile hazard. Replace backing pads when you notice reduced disc adhesion or if the Velcro surface appears compressed or damaged. When using aggressive-grade backing pads, be particularly mindful of vibration exposure—follow HSE guidelines for hand-arm vibration syndrome (HAVS) prevention by taking regular breaks and limiting daily exposure time.

Always wear appropriate personal protective equipment including dust masks or respirators compliant with relevant BS EN standards, safety glasses, and hearing protection when operating sanders. Even with excellent dust extraction, some airborne particles will be generated. Ensure adequate ventilation in your workspace and consider using a HEPA-filtered vacuum system to minimise dust exposure, particularly when sanding materials that may contain hazardous substances.

Frequently Asked Questions

How often should I replace my sander backing pad?

Replace your backing pad when you notice reduced adhesion of sanding discs, visible wear or compression of the rubber surface, or if the hook-and-loop Velcro becomes less effective. Professional tradespeople using sanders daily may need replacement every 6-12 months, while occasional users might get several years from a quality backing pad. Uneven wear patterns on your abrasive discs or increased vibration are also indicators that replacement is due.

Can I use a harder or softer pad than originally supplied with my sander?

Yes, changing the hardness grade is an excellent way to adapt your sander for different applications. Many professionals keep multiple backing pads of different hardnesses for the same tool. A softer pad than standard will improve conformability to curves and reduce the risk of cutting through edges, while a harder pad increases flatness and stock removal rates. Ensure the pad is designed for your specific sander model regardless of hardness grade.

What's the difference between 8-hole and multihole backing pads?

Eight-hole pads are the traditional standard offering good dust extraction for most applications. Multihole pads feature additional holes—sometimes 17 or more—that significantly improve dust extraction efficiency, keeping abrasive discs cleaner and extending their working life. You'll need to use compatible multihole sanding discs to benefit from the improved extraction. The enhanced performance is particularly noticeable when sanding materials that generate fine dust.

Why does my new backing pad seem to wear out the centre of my sanding discs faster?

This typically indicates that your new backing pad is harder than your previous worn pad, or you're applying excessive downward pressure during sanding. A hard pad requires a lighter touch—let the tool do the work rather than forcing it. If you're working on contoured surfaces, consider switching to a medium or soft backing pad. Ensure you're moving the sander continuously rather than dwelling in one spot, which concentrates wear.

Are universal backing pads as good as manufacturer-specific ones?

Manufacturer-specific backing pads are engineered precisely for particular sander models and generally offer the best fit, balance, and performance. However, quality universal backing pads can perform very well and offer cost savings or convenience when working with multiple tool brands. For professional applications where precision and reliability are paramount, original manufacturer pads from brands like Bosch Professional or Festool are recommended. For less critical work or budget-conscious purchases, quality universal options provide acceptable performance.