Utility Knives

Pay in 3 interest-free payments on purchases from £30-2000 with ![]() . Learn more.

. Learn more.

Loading...

Loading...

End of content

Error - No more pages to load

About Utility Knives

The utility knife is an indispensable cutting tool found in toolboxes across the UK, from construction sites to warehouse floors and home workshops. Often referred to as a trimming knife or generically as a "Stanley knife" due to the enduring popularity of that brand, the utility knife has earned its place as an everyday carry item for tradespeople and DIY enthusiasts alike. These versatile cutting tools are engineered for quick blade changes, typically using disposable double-ended blades that can be reversed when one edge becomes dull, maximising value and minimising downtime on the job.

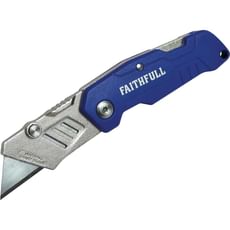

Modern utility knives come in various configurations to suit different working environments and applications. The classic retractable design features a sliding mechanism that safely conceals the blade when not in use, whilst folding variants offer a more compact profile for pocket carry. Fixed blade models provide maximum rigidity for heavy-duty cutting tasks. Many professional-grade utility knives incorporate thoughtful features such as integrated blade storage compartments, multiple blade positions for different cutting depths, tool-free blade changes, and ergonomic handles with TPE grips for extended comfort during repetitive cutting work.

Tooled-Up.com stocks an extensive selection of utility knives from trusted manufacturers including Bahco, Draper, Faithfull, Bosch Professional, Facom, and Bessey. Whether you need a basic trimming knife for opening packaging, a heavy-duty cutter for roofing felt and insulation materials, or a precision tool for craft work, the range available from Tooled-Up encompasses everything from budget-friendly options to premium professional models with advanced safety features and multi-function capabilities.

Jargon Buster

- Retractable Blade: A safety mechanism allowing the blade to slide back into the handle when not in use, reducing the risk of accidental cuts and protecting the blade edge during storage and transport.

- Snap-Off Blade: A segmented blade design where dulled sections can be snapped off to reveal a fresh sharp edge, extending blade life without requiring a complete replacement. Commonly used in heavy-duty applications.

- Fixed Blade: A utility knife design where the blade remains in a fixed, non-retractable position, offering maximum stability and strength for demanding cutting tasks requiring consistent pressure.

- Blade Storage Compartment: An integrated cavity within the knife handle designed to store spare blades, ensuring replacements are always to hand without needing to carry separate blade dispensers.

- Auto-Lock Mechanism: A safety feature that automatically locks the blade in position once extended, preventing accidental retraction during use which could cause blade slippage and potential injury.

- Squeeze-Grip Release: An ergonomic blade release system requiring the user to squeeze the handle to extend or retract the blade, providing enhanced safety as the blade automatically retracts when pressure is released.

Who Uses Utility Knives?

Utility knives serve a remarkably broad range of users across professional trades and domestic applications:

- Warehouse Operatives & Logistics Workers: Opening boxes, cutting packaging tape, and breaking down cardboard for recycling

- Electricians & Data Cablers: Stripping cable sheathing, trimming cable ties, and precise cutting of flexible conduit

- Carpenters & Joiners: Marking timber, shaving wood, cutting laminate edging, and trimming sealant beads

- Plasterers & Dry Liners: Cutting plasterboard, trimming scrim tape, and opening bags of plaster

- Roofers & Cladders: Cutting roofing felt, trimming membrane, and slicing insulation materials

- Decorators & Painters: Opening paint tins, cutting masking tape, trimming wallpaper edges, and scoring paint films

- Floor Layers: Cutting carpet, vinyl, and underlay with precision

- Shop Fitters & Signage Installers: Trimming vinyl graphics, cutting mounting board, and precise material preparation

- Facilities Maintenance & Caretakers: General purpose cutting tasks throughout buildings and grounds

- Craft Enthusiasts & Model Makers: Precision cutting of card, foam board, and lightweight materials

- DIY Enthusiasts & Homeowners: Countless household cutting tasks from opening deliveries to home improvement projects

How to Choose the Right Utility Knives

Blade Type and Compatibility: Consider whether you need standard trapezoidal blades for general purpose work, heavy-duty blades for demanding materials, or specialist blades such as hook blades for roofing felt and flooring. Ensure replacement blades are readily available and affordable for your chosen model.

Safety Features: Professional users subject to HSE regulations should prioritise knives with auto-retraction mechanisms, blade guards, and secure locking systems. Many modern designs feature squeeze-grip releases that automatically retract the blade when released, significantly reducing injury risk in busy working environments.

Handle Design and Ergonomics: For extended use, comfortable grip design becomes critical. Look for handles with soft-touch TPE overmoulding, ergonomic contouring, and sufficient size to prevent hand fatigue. Metal-bodied knives from brands like Bahco offer durability but may feel cold in winter site conditions, whilst polymer handles provide better insulation.

Retraction Mechanism: Choose between fixed, folding, and retractable designs based on your primary application. Retractable models offer versatility with adjustable blade depth, folding knives provide compact pocket carry, whilst fixed blade designs deliver maximum rigidity for heavy-duty cutting where blade flex could compromise accuracy.

Build Quality and Durability: Professional tradespeople should invest in robust construction from reputable manufacturers. The Tooled-Up range includes professional-grade options from Bosch Professional, Facom, and Bahco that withstand daily site use, whilst brands like Draper and Faithfull offer excellent value for lighter-duty applications.

Additional Features: Consider whether integrated features add genuine value for your work. Some models incorporate wire strippers, screwdriver bit holders, string cutters, or secondary blades. Whilst useful for multi-trade applications, these additions may add bulk for users requiring a slim-profile pocket knife.

Popular Accessories

- Replacement Blades: Bulk packs of standard trapezoidal blades, heavy-duty blades, and specialist profiles including hook blades and rounded-tip safety blades

- Blade Disposal Containers: Safe storage tins for used blades, essential for responsible disposal and workplace safety compliance

- Tool Lanyards & Tethers: Prevent dropped tools when working at height, meeting work-at-height regulations on construction sites

- Holsters & Sheaths: Belt-mounted carriers providing quick access whilst keeping blades safely secured during movement around site

- Cutting Mats & Straight Edges: Self-healing cutting mats and metal safety rulers for precision work in workshops and craft applications

- Sharpening Stones: For maintaining non-disposable knife blades and other edged tools

- Multi-Tool Accessories: Bit sets and attachments for utility knives with integrated screwdriver functionality

Safety Information

Utility knives are sharp-edged tools requiring respect and proper handling to prevent injury. Always retract or fold the blade immediately after use, never leaving a utility knife lying around with an exposed blade. When cutting, direct the blade away from your body and keep your free hand behind the cutting edge. Use appropriate PPE including cut-resistant gloves when performing repetitive cutting tasks or working with challenging materials.

Replace blades at the first sign of dullness – dull blades require excessive pressure which increases the likelihood of slippage and injury. Dispose of used blades responsibly in dedicated sharps containers, never loose in general waste where they pose a risk to waste handlers. On construction sites, ensure utility knife use complies with your employer's risk assessments and HSE guidelines regarding sharp tools.

Choose knives with appropriate safety features for your working environment. Auto-retracting models significantly reduce injury risk in fast-paced warehouse settings, whilst rounded-tip safety blades minimise puncture injuries when cutting near hands. Store utility knives securely when not in use, particularly in households with children, and consider models with blade locks to prevent accidental extension during transport in toolboxes or pockets.

Frequently Asked Questions

How often should I change utility knife blades?

Replace blades as soon as you notice increased cutting resistance, ragged cut edges, or the need to make multiple passes. For professional tradespeople performing repetitive cutting, this might mean daily blade changes. Many double-ended blades can be reversed once to effectively double their lifespan. Regular blade changes maintain cutting efficiency and actually improve safety by reducing the force required, which decreases the risk of slippage.

Are snap-off blades better than standard utility knife blades?

Both designs have distinct advantages for different applications. Snap-off blades offer extended use without blade changes – simply snap off the dulled segment to reveal a fresh edge. They're ideal for repetitive cutting tasks and situations where stopping to change blades disrupts workflow. Standard trapezoidal blades are typically more robust for heavy-duty applications, offer better blade stability, and are preferred for precision work. Many professionals carry both types for different tasks.

What's the difference between a utility knife and a safety knife?

Safety knives incorporate enhanced features specifically designed to reduce injury risk, such as auto-retracting blades that instantly retract when not under cutting pressure, concealed blades that never fully expose, or rounded tips that prevent puncture injuries. Whilst all modern utility knives include basic safety features like blade locks, dedicated safety knives are engineered for high-risk environments like food processing, warehouse operations, or anywhere HSE regulations demand maximum protection.

Can I take a utility knife through airport security?

No. Utility knives and loose blades are prohibited in aircraft cabin baggage under UK aviation security regulations. If you must travel with a utility knife, pack it in checked luggage only, ensuring the blade is safely retracted or the knife is securely packaged. Many tradespeople working away from home find it more practical to keep a basic utility knife in their checked toolbox rather than carrying one in hand luggage.

What makes professional utility knives worth the extra cost?

Professional-grade utility knives from manufacturers like Bahco, Bosch Professional, and Facom feature superior materials, more robust construction, and refined mechanisms that withstand daily trade use. Benefits include metal rather than plastic bodies, smoother blade advancement systems, more secure locking mechanisms, better ergonomics for extended use, and often tool-free blade changes. For tradespeople using their knife dozens of times daily, these improvements deliver better long-term value, enhanced safety, and reduced hand fatigue compared to budget alternatives.