Water Pumps

Featured Categories

New Products

Top Sellers

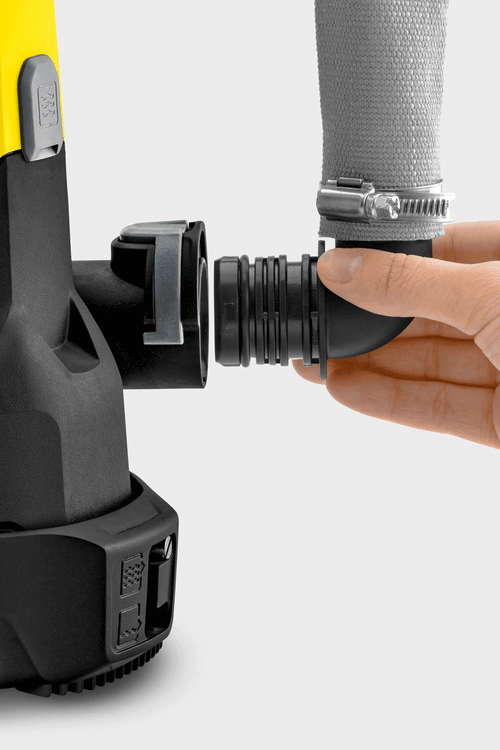

Karcher Adaptor to Allow Fitting 1/2" Garden Hose to Pumps or Taps with G1 (33mm) Thread

in stock

About Water Pumps

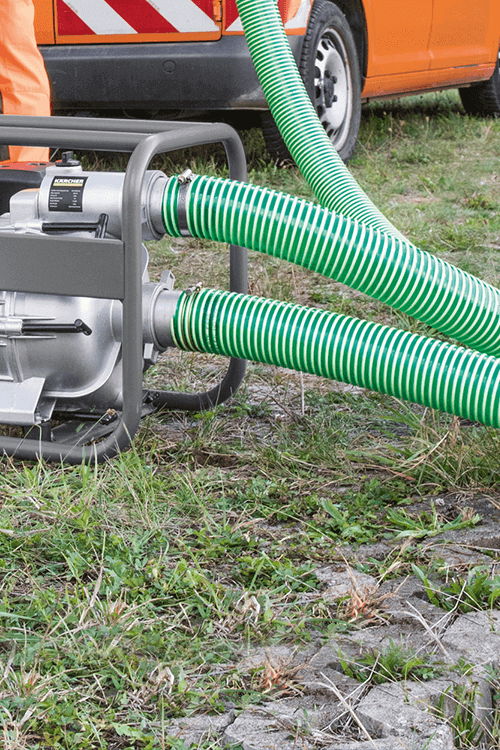

Water pumps are essential pieces of equipment designed to move large volumes of water quickly and efficiently from one location to another. Whether you're dealing with a flooded basement, draining a construction site trench, irrigating your garden, or transferring water from storage tanks and butts, the right water pump can save hours of manual labour whilst preventing water damage and costly delays. Tooled-Up.com stocks a comprehensive selection of water pumps suitable for both professional tradespeople and domestic users, covering everything from compact submersible pumps for emergency flood situations to heavy-duty surface-mounted units for continuous site work.

The water pump category encompasses two main types: submersible pumps that can be lowered directly into the water source, and surface-mounted pumps that must remain dry whilst drawing water through a suction hose. Submersible models typically feature automatic float switches that activate and deactivate the pump based on water levels, making them ideal for unattended operation. Surface pumps generally offer higher flow rates and are better suited to continuous pumping applications. The key distinction when selecting any water pump is whether it's designed for clean water (drinking water, swimming pools, water butts) or dirty water containing debris, silt, and particles up to 35mm in diameter.

Beyond the pumps themselves, this category includes essential accessories such as lay flat hoses for efficient water discharge, suction hose pipes designed to maintain their shape under vacuum, adaptors and connectors for linking different hose sizes and thread types, water pump filters to protect pump mechanisms from damage, and drill pumps that transform your power drill into a lightweight transfer pump for smaller applications.

Jargon Buster

- Flow Rate (Litres Per Hour/LPH): The volume of water a pump can move in one hour, typically ranging from 6,000 LPH for small domestic pumps to over 25,000 LPH for heavy-duty models. Higher flow rates mean faster water removal.

- Maximum Head (Metres): The maximum vertical height a pump can lift water from its source. This measurement decreases with horizontal distance, so always check manufacturer specifications for your specific setup.

- Float Switch: An automatic sensor found on submersible pumps that activates the unit when water reaches a certain level and switches it off when the level drops, preventing dry running which can damage the motor.

- Particle Size: The maximum diameter of solid debris a pump can handle without clogging. Clean water pumps typically manage particles up to 5mm, whilst dirty water pumps can handle debris between 20-38mm.

- Priming: The process of filling a surface pump's intake system with water to remove air and create the suction necessary for operation. Self-priming pumps can do this automatically, whilst others require manual priming.

- Dry Running Protection: A safety feature that automatically shuts down the pump if it runs without water, preventing motor burnout and extending the pump's working life.

Who Uses Water Pumps?

Water pumps serve a diverse range of users across professional and domestic applications:

- Builders and Construction Workers: For dewatering excavations, trenches, foundations, and flooded building sites

- Groundworkers and Civil Engineers: Managing water table issues during earthworks and drainage installation

- Plumbers and Heating Engineers: Emergency response to burst pipes, boiler leaks, and domestic flooding

- Landscapers and Gardeners: Irrigation systems, pond maintenance, and transferring water from collection butts

- Facilities Managers: Building maintenance, basement drainage, and emergency flood response

- Property Maintenance Companies: Responding to water ingress, leak damage, and drainage problems

- Farmers and Agricultural Workers: Livestock watering, irrigation, and field drainage

- Homeowners and DIY Enthusiasts: Garden irrigation, hot tub filling, emergency flood protection, and cellar drainage

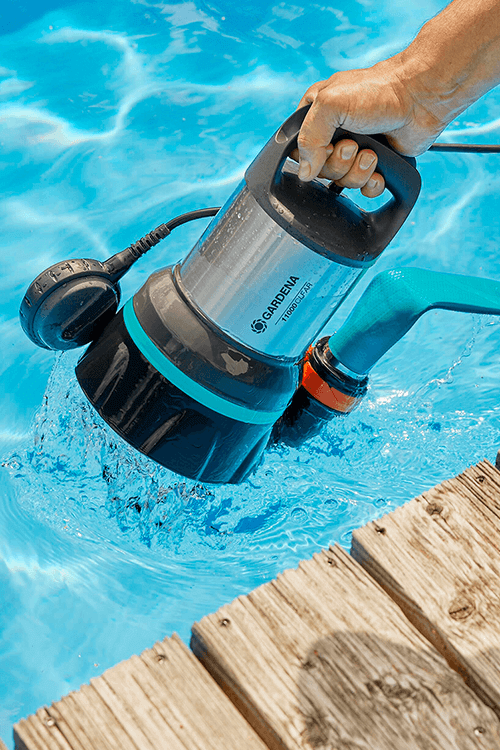

- Swimming Pool Technicians: Pool emptying, water circulation, and maintenance operations

How to Choose the Right Water Pumps

Selecting the appropriate water pump requires careful consideration of several key factors:

Water Type: Determine whether you're pumping clean water or dirty water containing debris. Clean water pumps are suitable for mains water, rainwater from butts, and swimming pools, whilst dirty water pumps are necessary for floodwater, construction site drainage, and any water containing silt, leaves, or solid particles. Using a clean water pump with dirty water will result in rapid clogging and potential damage.

Required Flow Rate: Calculate the volume you need to move and how quickly. For emergency flooding, higher flow rates (15,000-25,000 LPH) are crucial. For garden irrigation or routine transfers, moderate flow rates (6,000-12,000 LPH) are usually sufficient. The selection available at Tooled-Up includes pumps across the entire flow rate spectrum.

Pumping Distance and Height: Measure both the vertical lift (head) and horizontal distance the water must travel. Pump performance decreases with distance, so check manufacturer specifications carefully. As a general rule, every 10 metres of horizontal distance equals approximately 1 metre of vertical head.

Power Source: Most water pumps run on 240v mains power, requiring access to a standard UK socket protected by an RCD. For remote locations without electricity, petrol-powered pumps offer portability but require fuel and maintenance. Battery-powered pumps suit occasional light-duty applications.

Submersible vs Surface: Submersible pumps offer convenience for flooded areas, automatic operation via float switches, and quieter running since they're underwater. Surface pumps provide higher flow rates, easier maintenance access, and suit continuous operation from static water sources like ponds or tanks.

Inlet and Outlet Sizes: Larger diameter connections (typically 25mm to 50mm) allow higher flow rates. Ensure your hoses and fittings match the pump connections, or purchase appropriate adaptors and connectors.

Popular Accessories

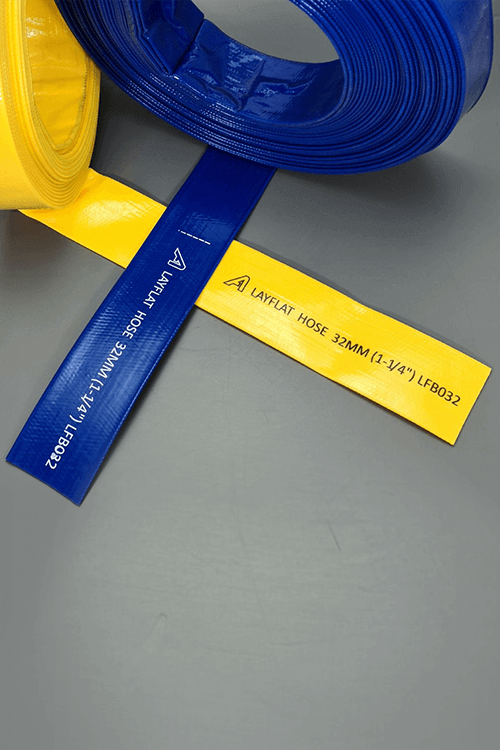

- Lay Flat Hoses: Collapsible discharge hoses in various lengths and diameters for efficient water transport and compact storage

- Suction Hose Pipes: Reinforced hoses that resist collapse under vacuum, essential for surface pump installations

- Hose Adaptors and Connectors: Couplings, reducers, and thread adaptors for connecting different hose sizes and pump types

- Water Pump Filters: Inline and intake filters that protect pump mechanisms from debris and extend service life

- Hose Clamps and Jubilee Clips: Secure connections preventing leaks and hose detachment under pressure

- Extension Cables: Outdoor-rated 240v extensions with RCD protection for reaching distant water sources

- Float Switches: Aftermarket automatic water level sensors for converting manual pumps to automatic operation

- Strainer Baskets: Coarse filtration accessories that prevent large debris entering pump intakes

- Drill Pumps: Compact transfer pumps powered by standard power drills for small-scale water movement

Safety Information

Electrical Safety: Water and electricity present serious hazards when combined. Always use pumps outdoors or in wet environments with RCD (Residual Current Device) protection rated at 30mA or less. Never handle electrical connections with wet hands, and ensure all 240v equipment complies with UK electrical safety standards. Keep plug connections above potential flood levels and use waterproof outdoor extension cables where necessary.

Manual Handling: Water pumps filled with water become significantly heavier. Follow proper manual handling techniques when lifting, and drain submersible pumps before removal where possible. Many larger models feature carrying handles – always use both hands and maintain proper lifting posture.

Dry Running Prevention: Never operate a water pump without adequate water supply. Dry running causes rapid overheating and motor failure. Choose models with dry running protection for unattended operation, or monitor water levels regularly during manual use.

Contaminated Water: When pumping floodwater or sewage-contaminated water, wear appropriate PPE including waterproof gloves, wellington boots, and eye protection. Thoroughly clean and disinfect equipment after use, and wash hands thoroughly. Be aware of potential biological hazards and sharp objects hidden in murky water.

Maintenance Safety: Disconnect pumps from the mains before performing any maintenance, cleaning, or inspection. Allow motors to cool completely before handling internal components. Store pumps in dry locations during off-season periods to prevent corrosion and frost damage.

Frequently Asked Questions

Q: What's the difference between a clean water pump and a dirty water pump?

A: Clean water pumps are designed for relatively particle-free water (up to 5mm solids) such as mains water, rainwater from storage butts, or swimming pools. They feature tighter tolerances and smaller impeller gaps for efficient pumping but will clog quickly with debris. Dirty water pumps handle contaminated water containing silt, leaves, and particles typically up to 20-38mm diameter, making them suitable for construction site drainage, floodwater, and pond clearing where debris is inevitable.

Q: Can I leave a submersible pump running unattended?

A: Yes, provided it features an automatic float switch and dry running protection. The float switch will activate the pump when water reaches a preset level and shut it off when levels drop, preventing damage from running dry. Always ensure the pump is connected through an RCD-protected circuit and positioned on a stable surface where it won't tip over or become blocked by debris.

Q: How do I calculate what flow rate I need?

A: Estimate the volume of water requiring removal and your desired timeframe. For example, to empty 10,000 litres in one hour, you'd need a pump rated at minimum 10,000 LPH. However, always add a safety margin since manufacturer flow rates assume ideal conditions – pumping height, distance, and hose restrictions all reduce actual performance. For emergency flooding situations, choose the highest flow rate your budget allows.

Q: Why has my surface pump lost suction?

A: Loss of suction typically results from air leaks in the intake system, loss of prime, or the suction hose collapsing under vacuum. Check all connections for tightness, ensure you're using proper reinforced suction hose (not standard lay flat hose on the intake side), verify the pump is properly primed with water, and confirm the suction lift doesn't exceed the pump's maximum head specification. Suction strainers can also become blocked, restricting water flow.

Q: Can I use a water pump to empty my fish pond?

A: Yes, but choose a dirty water pump rated for the particle size present in your pond. Standard clean water pumps will clog quickly with pond silt, algae, and organic debris. Position the pump intake above the pond bottom to avoid sucking up excessive sediment, and consider using a strainer basket. Never return fish to a pond immediately after refilling – allow time for temperature stabilisation and dechlorination of fresh tap water.